Table of Contents

Top Features to Look for in a Horizontal Wire Spooling Machine

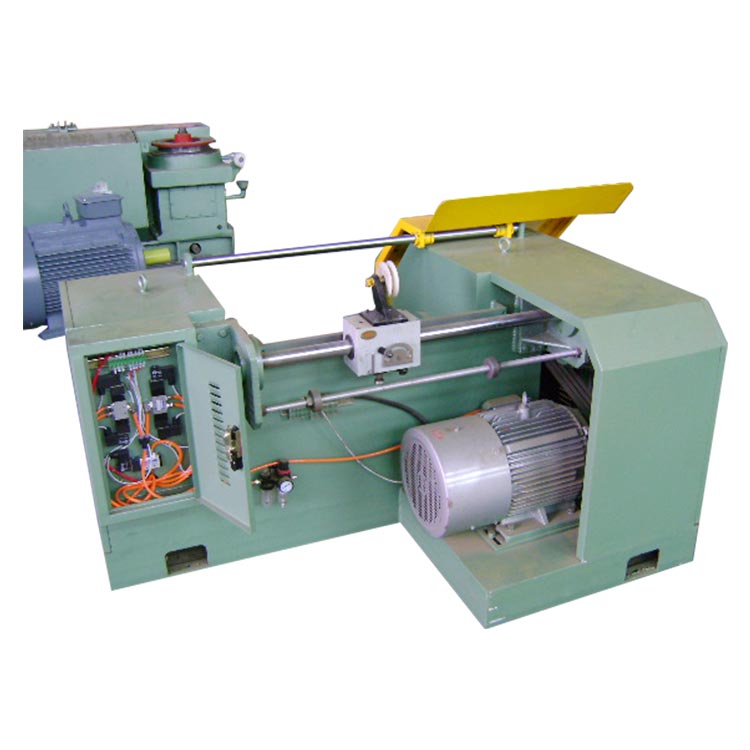

When it comes to wire spooling machines, there are a variety of options available on the market. One popular type is the horizontal wire spooling machine, which offers a number of advantages for businesses looking to efficiently spool wire. If you are in the market for a horizontal wire spooling machine, there are several key features to look for to ensure you are getting a high-quality and reliable machine.

One of the most important features to consider when choosing a horizontal wire spooling machine is the spooling capacity. The spooling capacity of a machine refers to the maximum amount of wire that can be spooled onto a single spool. This is an important consideration, as it will determine how much wire you can spool at one time and how often you will need to stop and change spools. Look for a machine with a high spooling capacity to maximize efficiency and minimize downtime.

Another important feature to look for in a Horizontal Spooler Of Wire Drawing Machine Process is the speed at which it can spool wire. The speed of the machine will determine how quickly you can spool wire, which can have a significant impact on your overall productivity. Look for a machine that offers variable speed control, so you can adjust the speed to suit your specific needs. Additionally, consider the overall efficiency of the machine, including how quickly it can set up and start spooling wire.

In addition to spooling capacity and speed, it is also important to consider the overall durability and reliability of the machine. Look for a machine that is made from high-quality materials and is built to last. A durable machine will be able to withstand the rigors of daily use and will require less maintenance over time. Additionally, consider the reputation of the manufacturer and look for machines that come with a warranty to protect your investment.

When choosing a horizontal wire spooling machine, it is also important to consider the overall ease of use and convenience of the machine. Look for a machine that is easy to set up and operate, with intuitive controls and clear instructions. Additionally, consider the overall size and footprint of the machine, as well as any additional features such as automatic wire tensioning or cutting capabilities. A machine that is easy to use and offers additional features can help streamline your wire spooling process and improve overall efficiency.

Finally, consider the overall cost of the machine and how it fits into your budget. While it is important to invest in a high-quality machine, it is also important to consider the overall cost and ensure that it aligns with your budget. Compare prices from different manufacturers and consider any additional costs such as installation or maintenance. Additionally, consider the overall return on investment of the machine, including how much time and money it can save you in the long run.

In conclusion, when choosing a horizontal wire spooling machine, there are several key features to look for to ensure you are getting a high-quality and reliable machine. Consider the spooling capacity, speed, durability, ease of use, and overall cost of the machine to make an informed decision. By choosing a machine that meets your specific needs and requirements, you can improve your wire spooling process and increase overall efficiency in your business.

Benefits of Using Horizontal Wire Spooling Machine

A horizontal wire spooling machine is a valuable piece of equipment that offers numerous benefits to industries that rely on wire spools for their operations. These machines are designed to efficiently wind wire onto spools in a horizontal orientation, making the process faster and more streamlined. In this article, we will explore the various benefits of using a horizontal wire spooling machine in your business.

One of the primary advantages of using a horizontal wire spooling machine is the increased efficiency it provides. These machines are capable of winding wire onto spools at a much faster rate than manual methods, saving valuable time and labor costs. This increased efficiency allows businesses to meet production deadlines more easily and keep up with demand without sacrificing quality.

In addition to improved efficiency, horizontal wire spooling machines also offer greater precision and consistency in the winding process. These machines are equipped with advanced technology that ensures the wire is wound onto the spool evenly and securely, reducing the risk of tangling or other issues that can arise with manual winding. This precision results in higher quality spools of wire that are less likely to cause problems during use.

Another benefit of using a horizontal Bobbin Spooling Machine is the reduction in waste that it provides. Manual wire winding can often result in wasted wire due to uneven winding or other errors. Horizontal wire spooling machines eliminate these issues, ensuring that every inch of wire is used efficiently and reducing the amount of waste generated during the spooling process. This not only saves money on materials but also helps businesses operate in a more sustainable manner.

Horizontal wire spooling machines are also incredibly versatile, capable of handling a wide range of wire sizes and types. This flexibility allows businesses to use the same machine for multiple applications, reducing the need for multiple pieces of equipment and saving valuable floor space in the process. Whether you are working with thin gauge wire or heavy-duty cable, a horizontal wire spooling machine can handle the job with ease.

Furthermore, horizontal wire spooling machines are designed with operator safety in mind. These machines are equipped with safety features such as guards and emergency stop buttons to protect workers from injury during operation. By automating the spooling process, businesses can reduce the risk of accidents and create a safer work environment for their employees.

In conclusion, the benefits of using a horizontal wire spooling machine in your business are clear. From increased efficiency and precision to reduced waste and improved safety, these machines offer a wide range of advantages that can help businesses operate more effectively and profitably. If you are in need of a reliable and versatile solution for your wire spooling needs, consider investing in a horizontal wire spooling machine today.

How to Properly Maintain Horizontal Wire Spooling Machine

Horizontal wire spooling machines are essential equipment in various industries that deal with wire products. These machines are used to wind wire onto spools in a precise and efficient manner. Proper maintenance of a horizontal wire spooling machine is crucial to ensure its optimal performance and longevity. In this article, we will discuss some key maintenance tips to help you keep your horizontal wire spooling machine in top condition.

Regular cleaning of the machine is the first step in maintaining its functionality. Dust, dirt, and debris can accumulate on the machine over time, leading to decreased performance and potential damage. Use a soft brush or cloth to remove any buildup on the machine’s surfaces, including the wire guides, spool holders, and tensioning mechanisms. Be sure to also clean the wire spools themselves to prevent any contamination that could affect the wire winding process.

Inspecting the machine for any signs of wear and tear is another important maintenance task. Check for loose or damaged parts, such as belts, gears, and bearings, and replace them as needed. Pay close attention to the wire guides and tensioning mechanisms, as these components are crucial for the proper winding of the wire onto the spools. Regularly lubricate moving parts to reduce friction and prevent premature wear.

Calibrating the machine is essential to ensure accurate wire winding. Check the tension settings and adjust them as needed to achieve the desired winding tension. Proper tensioning is crucial for preventing wire breakage and ensuring consistent spooling. Additionally, check the alignment of the wire guides to ensure that the wire is winding onto the spools evenly and without any snags or tangles.

Regularly monitoring the machine’s performance is key to identifying any issues before they escalate. Keep track of the wire winding speed, tension, and spooling quality to ensure that the machine is operating within the desired parameters. If you notice any deviations from the norm, investigate the cause and address it promptly to prevent further damage to the machine.

Training your operators on the proper use and maintenance of the horizontal wire spooling machine is crucial for its longevity. Ensure that your operators are familiar with the machine’s operation and maintenance procedures, and provide them with the necessary training and resources to perform these tasks effectively. Encourage them to report any issues or concerns regarding the machine’s performance so that they can be addressed promptly.

In conclusion, proper maintenance of a horizontal wire spooling machine is essential to ensure its optimal performance and longevity. By following the tips outlined in this article, you can keep your machine in top condition and prevent costly downtime due to equipment failure. Regular cleaning, inspection, calibration, monitoring, and operator training are key components of a comprehensive maintenance program for your horizontal wire spooling machine. By investing time and effort in maintaining your machine, you can extend its lifespan and maximize its productivity for years to come.