Table of Contents

Benefits of Using Horizontal Wire Spooling Machines in Industrial Applications

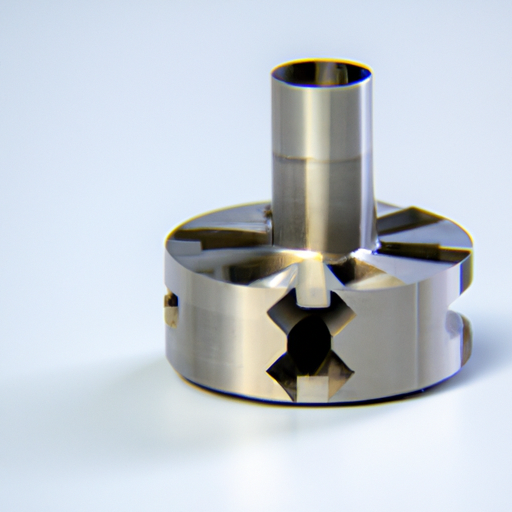

In industrial applications where wire spooling is a common task, the use of a horizontal wire spooling machine can offer numerous benefits. These machines are designed to efficiently wind wire onto spools in a horizontal orientation, making them ideal for a wide range of applications. From increased productivity to improved safety, there are many advantages to using a horizontal wire spooling machine in industrial settings.

One of the key benefits of using a horizontal wire spooling machine is the increase in productivity that it can provide. These machines are designed to quickly and efficiently wind wire onto spools, reducing the amount of time and labor required for this task. This can help to streamline production processes and increase overall efficiency in the workplace. By automating the wire spooling process, workers can focus on other tasks, leading to a more productive work environment.

Another advantage of using a horizontal wire spooling machine is the improved consistency and accuracy that it can offer. These machines are designed to wind wire onto spools with precision, ensuring that each spool is wound evenly and consistently. This can help to reduce waste and improve the quality of the finished product. By eliminating human error and variability, horizontal wire spooling machines can help to ensure that each spool meets the required specifications.

In addition to increased productivity and improved consistency, using a horizontal wire spooling machine can also help to improve safety in the workplace. These machines are designed with safety features such as guards and sensors to protect workers from potential hazards. By automating the wire spooling process, workers can avoid the risks associated with manual spooling, such as repetitive strain injuries and accidents. This can help to create a safer work environment and reduce the likelihood of workplace injuries.

Furthermore, horizontal wire spooling machines are versatile and can be used for a wide range of wire types and sizes. Whether you are working with thin gauge wire or heavy-duty cable, these machines can accommodate a variety of wire materials. This versatility makes horizontal wire spooling machines a valuable asset in industrial settings where different types of wire are used.

Overall, the benefits of using a horizontal wire spooling machine in industrial applications are clear. From increased productivity and improved consistency to enhanced safety and versatility, these machines offer a range of advantages that can help to streamline production processes and improve overall efficiency in the workplace. By investing in a horizontal wire spooling machine, industrial businesses can enjoy these benefits and achieve greater success in their operations.

How to Properly Maintain and Troubleshoot Horizontal Wire Spooling Machine

Horizontal wire Bobbin Spooling Machine is essential tools in various industries that deal with wire and cable production. These machines are designed to wind wire onto spools in a horizontal orientation, making the process more efficient and streamlined. Proper maintenance and troubleshooting of these machines are crucial to ensure smooth operation and prevent costly downtime.

One of the key aspects of maintaining a horizontal wire spooling machine is regular cleaning and lubrication. Dust, dirt, and debris can accumulate on the machine’s components, leading to increased friction and wear. It is important to clean the machine regularly using a soft brush or cloth to remove any buildup. Additionally, lubricating the moving parts with a suitable lubricant will help reduce friction and prolong the machine’s lifespan.

Another important maintenance task is inspecting the machine for any signs of wear or damage. Check the spooling mechanism, drive system, and electrical components for any loose or broken parts. Replace any worn-out components immediately to prevent further damage and ensure the machine’s optimal performance.

In addition to regular maintenance, troubleshooting is also a crucial aspect of ensuring the smooth operation of a horizontal wire spooling machine. When the machine is not functioning properly, it is important to identify the root cause of the issue and address it promptly.

One common issue with horizontal wire spooling machines is uneven winding of the wire onto the spool. This can be caused by a misaligned spooling mechanism or improper tension settings. To troubleshoot this issue, check the alignment of the spooling mechanism and adjust the tension settings as needed. Additionally, inspect the wire guide and ensure that it is properly positioned to guide the wire onto the spool evenly.

Another common problem with horizontal wire spooling machines is jamming of the wire during the spooling process. This can be caused by a misaligned wire guide or a buildup of debris on the spooling mechanism. To troubleshoot this issue, check the wire guide for any obstructions and clean the spooling mechanism thoroughly. Additionally, ensure that the wire is fed onto the spool in a straight and consistent manner to prevent jamming.

It is important to follow the manufacturer’s guidelines for maintenance and troubleshooting of a horizontal wire spooling machine. Regularly inspecting the machine, cleaning and lubricating its components, and addressing any issues promptly will help ensure its optimal performance and longevity.

In conclusion, proper maintenance and troubleshooting are essential for ensuring the smooth operation of a horizontal wire spooling machine. By following the manufacturer’s guidelines and addressing any issues promptly, you can prevent costly downtime and prolong the machine’s lifespan. Remember to clean, lubricate, and inspect the machine regularly to keep it running smoothly and efficiently.