Table of Contents

Benefits of Using Horizontal Wire Spooling Machine in Industrial Applications

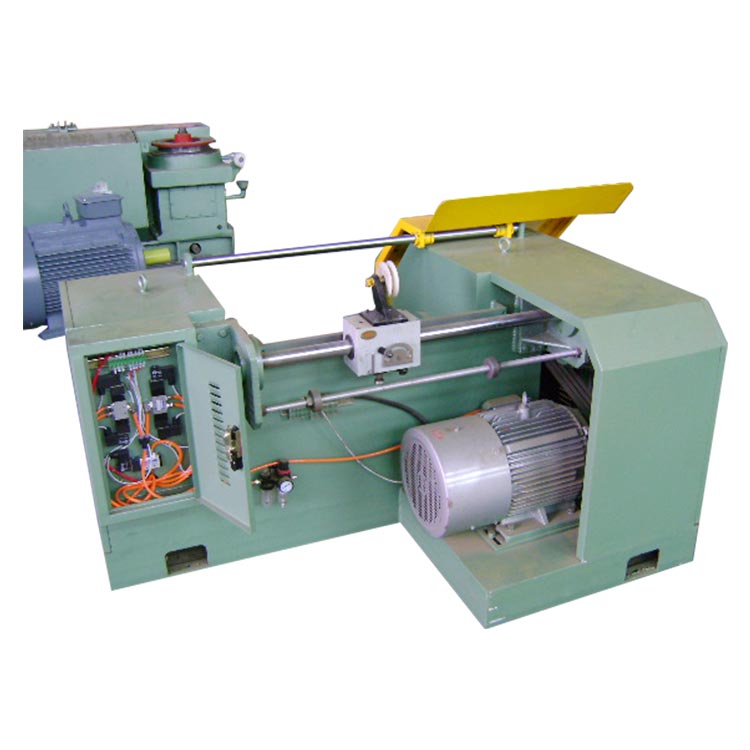

Horizontal wire spooling machines have become an essential tool in various industrial applications due to their efficiency and reliability. These machines are designed to wind wire onto a spool in a horizontal orientation, making them ideal for applications where space is limited or where a vertical spooling machine is not practical.

One of the key benefits of using a horizontal wire spooling machine is its ability to increase productivity. By automating the spooling process, these machines can significantly reduce the time and labor required to wind wire onto a spool. This not only saves time but also allows workers to focus on other tasks, ultimately improving overall efficiency in the workplace.

In addition to increasing productivity, horizontal wire spooling machines also help to improve the quality of the spooled wire. These machines are designed to ensure that the wire is wound evenly and tightly onto the spool, reducing the risk of tangles or snags during use. This results in a more consistent and reliable product, which is essential in industries where precision is key.

Furthermore, horizontal wire spooling machines are versatile and can accommodate a wide range of wire sizes and types. This flexibility allows businesses to use the same machine for different applications, saving both time and money. Whether spooling thin gauge wire for electronics or heavy-duty wire for construction, a horizontal wire spooling machine can handle the job with ease.

Another advantage of using a horizontal wire spooling machine is its compact design. Unlike vertical spooling machines, which require a significant amount of vertical space, horizontal machines can be easily integrated into existing production lines or workspaces. This makes them ideal for businesses with limited space or those looking to optimize their layout for maximum efficiency.

Additionally, horizontal wire spooling machines are easy to operate and maintain. Most machines come equipped with user-friendly controls and interfaces, making them accessible to workers of all skill levels. Routine maintenance tasks are also straightforward, ensuring that the machine remains in optimal working condition for years to come.

Overall, the benefits of using a horizontal wire spooling machine in industrial applications are clear. From increased productivity and improved quality to versatility and ease of use, these machines offer a range of advantages that can help businesses streamline their operations and stay competitive in today’s fast-paced market.

In conclusion, horizontal wire spooling machines are a valuable asset for any business looking to enhance their wire spooling process. With their efficiency, reliability, and versatility, these machines offer a range of benefits that can help businesses improve productivity, quality, and overall efficiency. Whether used in electronics manufacturing, construction, or any other industry that requires wire spooling, a horizontal wire spooling machine is a smart investment that can pay dividends for years to come.

Maintenance Tips for Horizontal Wire Spooling Machine

Horizontal wire spooling machines are essential equipment in various industries that deal with wire products. These machines are used to wind wire onto spools for storage or transportation purposes. To ensure the smooth operation of a horizontal wire spooling machine, regular maintenance is crucial. In this article, we will discuss some maintenance tips that can help prolong the lifespan of your horizontal wire spooling machine.

One of the most important maintenance tasks for a horizontal wire spooling machine is to regularly inspect and lubricate the moving parts. Over time, the friction between these parts can cause wear and tear, leading to decreased efficiency and potential breakdowns. By applying lubricant to the moving parts, you can reduce friction and prevent premature wear. It is recommended to use a high-quality lubricant that is suitable for the specific components of your machine.

In addition to lubrication, it is also important to check the tension of the wire on the spool regularly. Improper tension can lead to wire breakage or uneven winding, which can affect the quality of the final product. To ensure proper tension, you can adjust the tension settings on the machine according to the type and thickness of the wire being spooled. It is also important to inspect the spooling process regularly to ensure that the wire is being wound onto the spool evenly and without any kinks or tangles.

Another important maintenance task for a horizontal wire spooling machine is to clean the machine regularly. Dust, dirt, and debris can accumulate on the machine over time, which can affect its performance and efficiency. By cleaning the machine regularly, you can prevent build-up and ensure that the machine operates smoothly. Use a soft brush or cloth to remove any debris from the machine, and avoid using harsh chemicals that can damage the components.

In addition to regular maintenance tasks, it is also important to schedule periodic inspections by a qualified technician. A professional inspection can help identify any potential issues with the machine before they escalate into major problems. During the inspection, the technician can check for signs of wear and tear, loose or damaged parts, and any other issues that may affect the performance of the machine. By addressing these issues early on, you can prevent costly repairs and downtime in the future.

In conclusion, proper maintenance is essential for ensuring the smooth operation of a horizontal wire spooling machine. By following these maintenance tips, you can prolong the lifespan of your machine and prevent breakdowns. Regular inspection, lubrication, tension adjustment, and cleaning are all important tasks that should be included in your maintenance routine. Additionally, scheduling periodic inspections by a qualified technician can help identify any potential issues early on. By taking care of your horizontal wire spooling machine, you can ensure that it continues to operate efficiently and effectively for years to come.