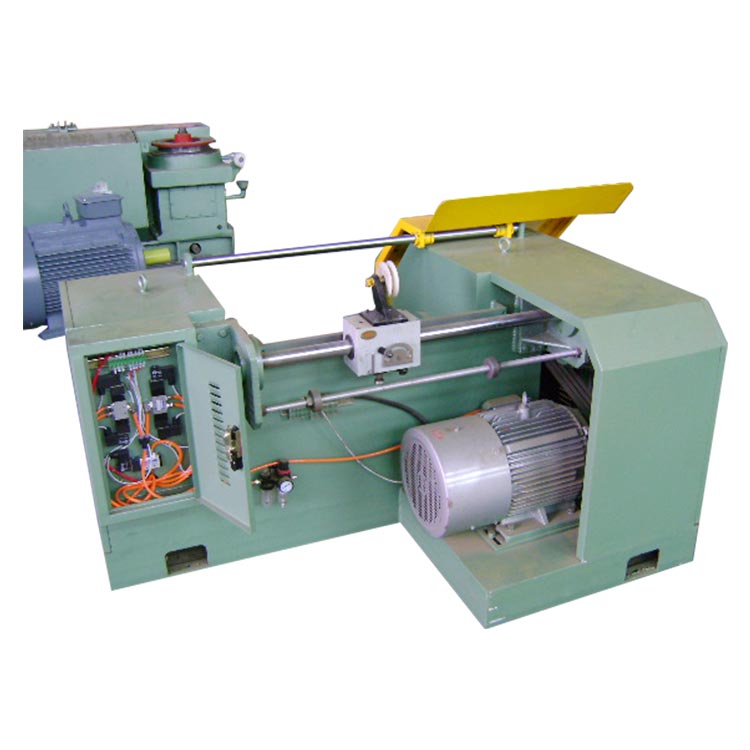

Maintenance Tips For Horizontal Wire Spooling Machine

Horizontal wire spooling machines are essential equipment in various industries that deal with wire products. These machines are used to wind wire onto spools for storage or transportation purposes. To ensure the smooth operation of a horizontal wire spooling machine, regular maintenance is crucial. In this article, we will discuss some maintenance tips that can help prolong the lifespan of your horizontal wire spooling machine.

One of the most important maintenance tasks for a horizontal wire spooling machine is to regularly inspect and lubricate the moving parts. Over time, the friction between these parts can cause wear and tear, leading to decreased efficiency and potential breakdowns. By applying lubricant to the moving parts, you can reduce friction and prevent premature wear. It is recommended to use a high-quality lubricant that is suitable for the specific components of your machine.

In addition to lubrication, it is also important to check the tension of the wire on the spool regularly. Improper tension can lead to wire breakage or uneven winding, which can affect the quality of the final product. To ensure proper tension, you can adjust the tension settings on the machine according to the type and thickness of the wire being spooled. It is also important to inspect the spooling process regularly to ensure that the wire is being wound onto the spool evenly and without any kinks or tangles.

Another important maintenance task for a Horizontal Spooler Of Wire Drawing Machine Process is to clean the machine regularly. Dust, dirt, and debris can accumulate on the machine over time, which can affect its performance and efficiency. By cleaning the machine regularly, you can prevent build-up and ensure that the machine operates smoothly. Use a soft brush or cloth to remove any debris from the machine, and avoid using harsh chemicals that can damage the components.

In addition to regular maintenance tasks, it is also important to schedule periodic inspections by a qualified technician. A professional inspection can help identify any potential issues with the machine before they escalate into major problems. During the inspection, the technician can check for signs of wear and tear, loose or damaged parts, and any other issues that may affect the performance of the machine. By addressing these issues early on, you can prevent costly repairs and downtime in the future.

In conclusion, proper maintenance is essential for ensuring the smooth operation of a horizontal wire spooling machine. By following these maintenance tips, you can prolong the lifespan of your machine and prevent breakdowns. Regular inspection, lubrication, tension adjustment, and cleaning are all important tasks that should be included in your maintenance routine. Additionally, scheduling periodic inspections by a qualified technician can help identify any potential issues early on. By taking care of your horizontal wire spooling machine, you can ensure that it continues to operate efficiently and effectively for years to come.