Table of Contents

Advantages of Using Horizontal Wire Drawing Machine

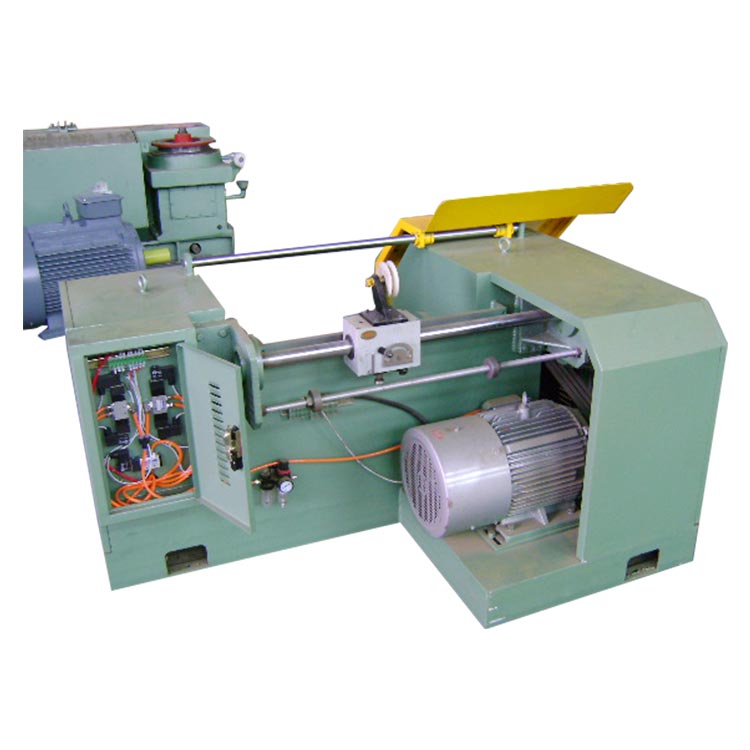

A horizontal wire drawing machine is a crucial piece of equipment used in the manufacturing industry to produce wire of various diameters. This machine operates by pulling a metal wire through a series of dies to reduce its diameter and improve its quality. There are several advantages to using a horizontal wire drawing machine, making it a popular choice for many manufacturers.

One of the main advantages of a horizontal wire drawing machine is its ability to produce wire with consistent diameter and surface finish. This is essential for industries that require high-quality wire for their products, such as the automotive, aerospace, and construction industries. The machine’s precise control over the drawing process ensures that the wire meets the required specifications, resulting in a uniform product that is free from defects.

Another advantage of using a horizontal wire drawing machine is its efficiency in producing wire at a high speed. The machine can draw wire at a rapid rate, allowing manufacturers to meet their production targets quickly and efficiently. This is particularly important for industries with high demand for wire products, as it helps to reduce lead times and increase overall productivity.

Furthermore, a horizontal wire drawing machine is versatile and can be used to draw wire of various materials, including steel, copper, aluminum, and brass. This flexibility allows manufacturers to produce a wide range of wire products to meet the diverse needs of their customers. Whether it is for electrical wiring, fencing, or industrial applications, the machine can handle different materials with ease, making it a valuable asset for any manufacturing operation.

In addition to its versatility, a horizontal wire drawing machine is also cost-effective in the long run. The machine’s high efficiency and productivity help to reduce operating costs and increase profitability for manufacturers. By producing wire at a faster rate and with higher quality, the machine enables manufacturers to save time and resources, ultimately leading to higher returns on investment.

Moreover, a horizontal wire drawing machine is easy to operate and maintain, making it suitable for both small-scale and large-scale manufacturing operations. The machine’s user-friendly interface and automated features simplify the drawing process, allowing operators to produce wire with minimal supervision. Additionally, routine maintenance tasks are straightforward and can be performed by in-house technicians, reducing downtime and ensuring continuous operation of the machine.

Overall, the advantages of using a horizontal wire drawing machine are clear. From its ability to produce high-quality wire with consistent diameter and surface finish to its efficiency in drawing wire at a high speed, the machine offers numerous benefits for manufacturers. Its versatility in handling different materials, cost-effectiveness, and ease of operation make it a valuable asset for any manufacturing operation looking to improve productivity and profitability. With these advantages in mind, it is no wonder that horizontal wire drawing machines are widely used in various industries around the world.

Maintenance Tips for Horizontal Wire Drawing Machine

A horizontal wire drawing machine is a crucial piece of equipment in the manufacturing industry, used to reduce the diameter of wire by pulling it through a series of dies. This process is essential for producing wires of various sizes and shapes for a wide range of applications. To ensure the smooth operation and longevity of your horizontal wire drawing machine, regular maintenance is key.

One of the most important maintenance tasks for a horizontal wire drawing machine is keeping the machine clean. Dust, dirt, and debris can build up on the machine over time, causing it to operate less efficiently and potentially leading to breakdowns. Regularly cleaning the machine with a soft cloth and mild detergent can help prevent these issues and keep your machine running smoothly.

In addition to keeping the machine clean, it is also important to regularly inspect and lubricate the moving parts of the machine. This includes the bearings, gears, and rollers, which can wear out over time and cause the machine to malfunction. By inspecting these parts regularly and lubricating them as needed, you can help prevent premature wear and extend the life of your horizontal wire drawing machine.

Another important maintenance task for a horizontal wire drawing machine is checking and adjusting the tension of the wire. Proper tension is essential for achieving the desired diameter of the wire and preventing breakages during the drawing process. By regularly checking and adjusting the tension of the wire, you can ensure that your machine is operating at its best and producing high-quality wire.

It is also important to regularly inspect the dies of the horizontal wire drawing machine. The dies are responsible for reducing the diameter of the wire as it is pulled through the machine, and they can wear out over time. By inspecting the dies regularly and replacing them as needed, you can ensure that your machine is producing wire of the correct size and shape.

In addition to these regular maintenance tasks, it is also important to schedule periodic maintenance checks with a qualified technician. A professional technician can inspect the machine for any potential issues, make any necessary repairs, and ensure that the machine is operating at its best. By scheduling regular maintenance checks, you can help prevent costly breakdowns and keep your horizontal wire drawing machine running smoothly.

In conclusion, regular maintenance is essential for ensuring the smooth operation and longevity of a horizontal wire drawing machine. By keeping the machine clean, inspecting and lubricating moving parts, checking and adjusting wire tension, inspecting dies, and scheduling periodic maintenance checks with a qualified technician, you can help prevent breakdowns and keep your machine running at its best. With proper maintenance, your horizontal wire drawing machine can continue to produce high-quality wire for years to come.

How to Choose the Right Horizontal Wire Drawing Machine for Your Business

When it comes to choosing the right horizontal wire drawing machine for your business, there are several factors to consider. This piece of equipment plays a crucial role in the wire drawing process, so it’s important to select one that meets your specific needs and requirements.

One of the first things to consider when choosing a horizontal wire drawing machine is the type of wire you will be working with. Different machines are designed to handle different types of wire, so it’s essential to choose one that is compatible with the materials you will be using. Whether you are working with steel, copper, aluminum, or another type of metal, make sure the machine you select is capable of handling the specific wire gauge and material you will be working with.

Another important factor to consider is the production capacity of the machine. Depending on the size of your business and the volume of wire you need to produce, you will need to choose a machine that can keep up with your production demands. Consider factors such as the speed of the machine, the number of dies it can accommodate, and the overall efficiency of the machine to ensure that it can meet your production needs.

In addition to production capacity, it’s also important to consider the quality of the wire produced by the machine. Look for a machine that is capable of producing high-quality wire with consistent diameter and surface finish. This will not only ensure the quality of your products but also help to minimize waste and improve overall efficiency.

When choosing a horizontal wire drawing machine, it’s also important to consider the overall durability and reliability of the machine. Look for a machine that is built to last and can withstand the rigors of daily use. Consider factors such as the materials used in construction, the quality of the components, and the reputation of the manufacturer to ensure that you are investing in a machine that will provide reliable performance for years to come.

Finally, consider the overall cost of the machine, including both the initial purchase price and ongoing maintenance and operating costs. While it’s important to choose a machine that meets your production needs and quality standards, it’s also important to consider your budget and ensure that the machine you choose is a cost-effective investment for your business.

In conclusion, choosing the right horizontal wire drawing machine for your business is a crucial decision that can have a significant impact on the quality and efficiency of your wire drawing process. By considering factors such as the type of wire you will be working with, production capacity, wire quality, durability, and cost, you can select a machine that meets your specific needs and helps to drive the success of your business. Take the time to research and compare different machines to ensure that you make an informed decision that will benefit your business in the long run.