Exploring the Benefits of Using a Horizontal Spooler Of Wire Drawing Machine Process

Wire drawing is a process used in the manufacturing industry to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of various sizes and shapes that are used in a wide range of applications, from electrical wiring to fencing. One crucial component of the wire drawing process is the spooler, which is used to wind the drawn wire onto a spool for storage and transportation.

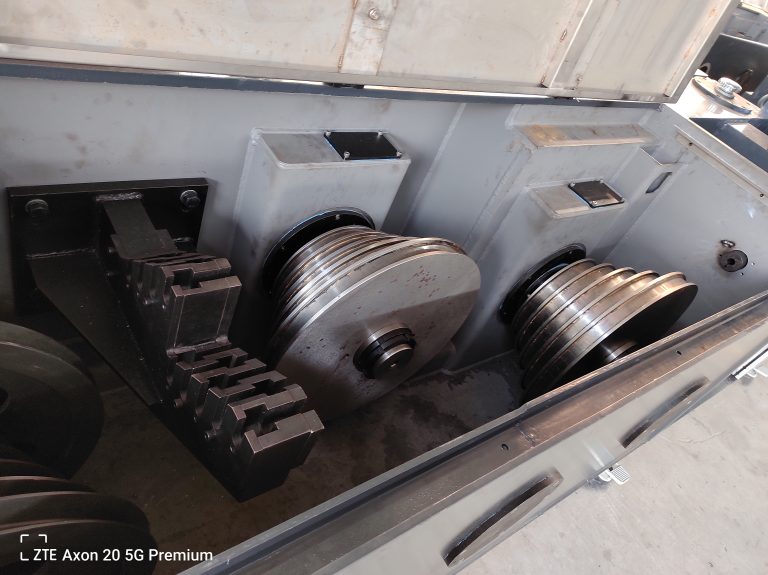

There are two main types of spoolers used in wire drawing machines: vertical spoolers and horizontal spoolers. While both types serve the same purpose, there are distinct advantages to using a horizontal spooler in the wire drawing process.

One of the primary benefits of using a horizontal spooler is its space-saving design. Horizontal spoolers are typically more compact than vertical spoolers, making them ideal for facilities with limited space. This can be particularly advantageous for smaller manufacturing operations or workshops where space is at a premium.

Additionally, horizontal spoolers offer greater flexibility in terms of spool size and configuration. Unlike vertical spoolers, which are limited by the height of the machine, horizontal spoolers can accommodate a wider range of spool sizes and shapes. This versatility allows manufacturers to customize their spooling process to meet the specific requirements of their production line.

Another key advantage of using a Wire Spooling Machine is its ease of operation. Horizontal spoolers are typically easier to load and unload than vertical spoolers, making them more user-friendly for operators. This can help to streamline the wire drawing process and improve overall efficiency in the manufacturing facility.

In addition to their space-saving design and ease of operation, horizontal spoolers also offer improved safety features compared to vertical spoolers. Horizontal spoolers are typically equipped with safety guards and sensors to prevent accidents and injuries during the spooling process. This can help to create a safer working environment for operators and reduce the risk of workplace accidents.

Furthermore, horizontal spoolers are often more cost-effective than vertical spoolers. The compact design of horizontal spoolers requires less material and energy to manufacture, resulting in lower production costs. Additionally, the ease of operation and improved efficiency of horizontal spoolers can help to reduce labor costs and increase overall productivity in the manufacturing facility.

Overall, the benefits of using a horizontal spooler in the wire drawing machine process are clear. From their space-saving design and flexibility to their ease of operation and improved safety features, horizontal spoolers offer a range of advantages that can help manufacturers streamline their production processes and improve overall efficiency. By investing in a horizontal spooler for their wire drawing machine, manufacturers can enhance their operations and stay ahead of the competition in the fast-paced manufacturing industry.