Table of Contents

Tips for Proper Maintenance of a Horizontal Bobbin Spooling Machine

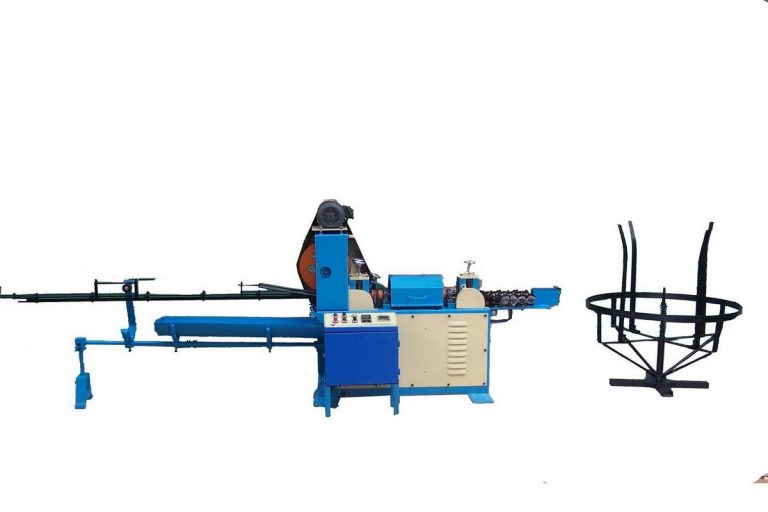

A horizontal bobbin spooling machine is a crucial piece of equipment in the textile industry. It is used to wind yarn onto bobbins, which are then used in various textile processes such as weaving and knitting. Proper maintenance of a horizontal bobbin spooling machine is essential to ensure its smooth operation and longevity. In this article, we will discuss some tips for proper maintenance of a horizontal bobbin spooling machine.

First and foremost, it is important to regularly clean the machine to prevent the buildup of dust, lint, and other debris. This can be done by using a soft brush or cloth to remove any dirt that may have accumulated on the machine. It is also important to regularly lubricate the moving parts of the Wire Spooling Machine to ensure smooth operation. This can be done using a lubricant recommended by the manufacturer.

In addition to cleaning and lubricating the machine, it is important to regularly inspect the machine for any signs of wear and tear. This includes checking for loose or damaged parts, as well as any unusual noises or vibrations during operation. If any issues are detected, it is important to address them promptly to prevent further damage to the machine.

Another important aspect of proper maintenance is to ensure that the tension on the yarn is properly adjusted. This can be done by adjusting the tension control knob on the machine to achieve the desired tension. Improper tension can result in uneven winding of the yarn onto the bobbin, which can affect the quality of the finished product.

It is also important to regularly check the alignment of the machine to ensure that it is operating correctly. This can be done by visually inspecting the machine for any misalignment or by using a straight edge to check the alignment of the various components. Misalignment can result in uneven winding of the yarn onto the bobbin, as well as increased wear and tear on the machine.

Regularly inspecting and replacing worn or damaged parts is also important for proper maintenance of a horizontal bobbin spooling machine. This includes checking the condition of the bobbins, as well as the tension control knob and other components. If any parts are found to be worn or damaged, they should be replaced promptly to prevent further damage to the machine.

In conclusion, proper maintenance of a horizontal bobbin spooling machine is essential to ensure its smooth operation and longevity. This includes regularly cleaning and lubricating the machine, inspecting for wear and tear, adjusting the tension on the yarn, checking the alignment of the machine, and inspecting and replacing worn or damaged parts. By following these tips, you can help ensure that your horizontal bobbin spooling machine operates efficiently and effectively for years to come.

Benefits of Using a Horizontal Bobbin Spooling Machine

A horizontal bobbin spooling machine is a piece of equipment used in the textile industry to wind thread onto bobbins. This machine offers several benefits that make it a valuable tool for textile manufacturers. In this article, we will explore the advantages of using a horizontal bobbin spooling machine.

One of the main benefits of using a horizontal bobbin spooling machine is its efficiency. This machine is designed to wind thread onto bobbins quickly and accurately, saving time and labor costs for textile manufacturers. The horizontal design of the machine allows for smooth and consistent winding, ensuring that each bobbin is filled evenly and without tangles.

Additionally, a Horizontal Spooler Of Wire Drawing Machine Process is versatile and can be used with a variety of thread types and sizes. This flexibility allows textile manufacturers to use the machine for a wide range of projects, making it a valuable investment for any production facility. Whether working with fine silk thread or heavy-duty industrial thread, a horizontal bobbin spooling machine can handle the job with ease.

Another benefit of using a horizontal bobbin spooling machine is its compact size. Unlike some other types of winding machines, a horizontal bobbin spooling machine takes up minimal floor space, making it ideal for smaller production facilities or workshops with limited space. This compact design also makes the machine easy to move and transport, allowing manufacturers to set up temporary winding stations as needed.

In addition to its efficiency and versatility, a horizontal bobbin spooling machine offers improved thread tension control. This feature is essential for ensuring the quality of the wound bobbins, as proper tension control prevents thread breakage and ensures a smooth winding process. With a horizontal bobbin spooling machine, manufacturers can adjust the tension settings to suit the specific requirements of each project, resulting in consistently high-quality bobbins.

Furthermore, a horizontal bobbin spooling machine is easy to operate and maintain. Most models come with user-friendly controls and settings that allow operators to quickly set up and start the winding process. Additionally, routine maintenance tasks such as cleaning and lubricating the machine are straightforward and can be performed by in-house staff, reducing downtime and ensuring the machine operates at peak efficiency.

Overall, the benefits of using a horizontal bobbin spooling machine make it an essential tool for textile manufacturers looking to improve their production processes. From its efficiency and versatility to its compact size and improved tension control, this machine offers a range of advantages that can help manufacturers increase productivity and reduce costs. Whether working with delicate fabrics or heavy-duty materials, a horizontal bobbin spooling machine is a valuable asset that can streamline the winding process and improve the quality of the finished products.