Advantages of Using High Speed Coilers in Horizontal Capstan Systems

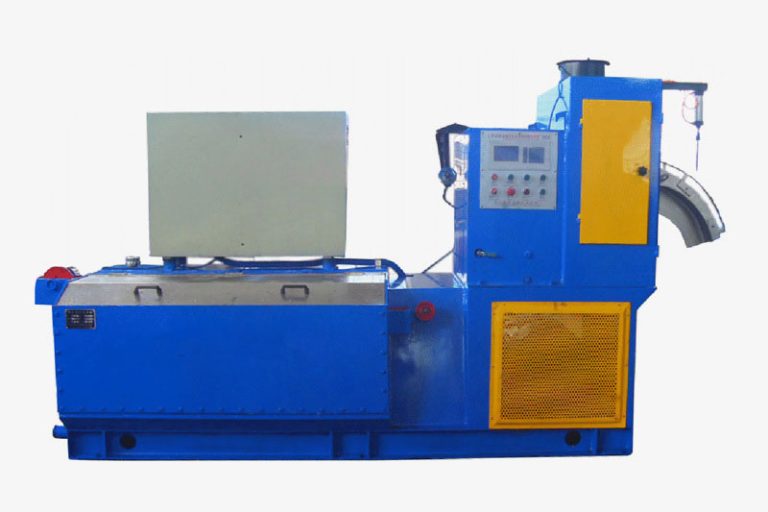

High speed coilers play a crucial role in horizontal capstan systems, offering a range of advantages that make them a popular choice for various industries. These coilers are designed to efficiently wind and coil materials such as wire, cable, rope, and tubing at high speeds, providing a reliable and cost-effective solution for production processes.

One of the key advantages of using high speed coilers in horizontal capstan systems is their ability to increase productivity. By winding materials quickly and efficiently, these coilers can significantly reduce the time required for coiling operations, allowing for higher output levels and improved efficiency in manufacturing processes. This increased productivity can lead to cost savings and improved profitability for businesses.

In addition to boosting productivity, high speed coilers also offer enhanced precision and consistency in coiling operations. These coilers are equipped with advanced technology and automation features that ensure accurate and uniform winding of materials, resulting in high-quality coils that meet the required specifications. This level of precision is essential for industries that demand strict quality control standards, such as the automotive, aerospace, and electronics sectors.

Furthermore, high speed coilers are designed to handle a wide range of materials and diameters, making them versatile and adaptable to different production requirements. Whether coiling thin wires or thick cables, these coilers can accommodate various sizes and types of materials, providing flexibility and scalability for businesses with diverse product lines. This versatility allows manufacturers to streamline their operations and meet the changing demands of the market.

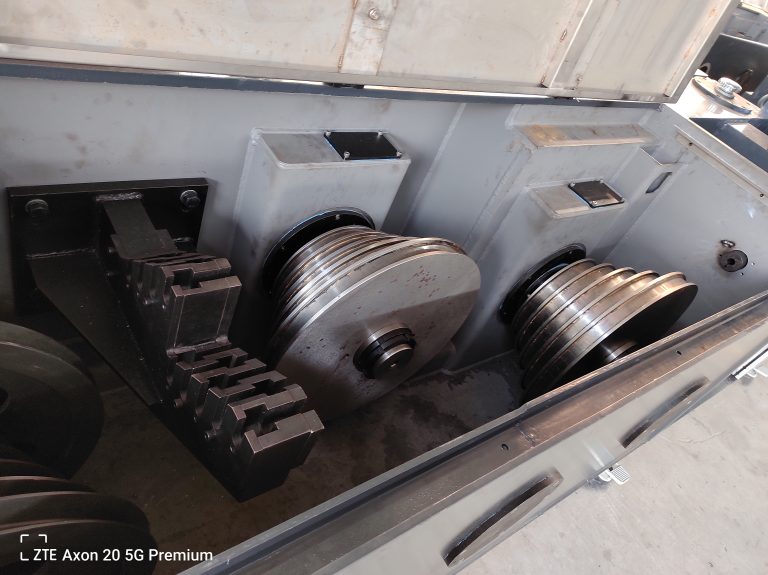

Another advantage of using high speed coilers in horizontal capstan systems is their durability and reliability. These coilers are built to withstand the rigors of continuous operation, with robust construction and high-quality components that ensure long-lasting performance. This reliability is essential for businesses that rely on consistent production output and minimal downtime to meet customer demands and deadlines.

Moreover, high speed coilers are designed for ease of use and maintenance, with user-friendly interfaces and intuitive controls that simplify operation and troubleshooting. This user-friendly design reduces the need for extensive training and technical expertise, allowing operators to quickly learn how to operate the coilers effectively. Additionally, these coilers are equipped with diagnostic tools and monitoring systems that help identify and address potential issues before they escalate, minimizing downtime and maximizing productivity.

In conclusion, high speed coilers offer a range of advantages for businesses looking to improve their coiling operations in horizontal capstan systems. From increased productivity and precision to versatility and reliability, these coilers provide a cost-effective solution for manufacturers across various industries. By investing in high speed coilers, businesses can enhance their production processes, meet quality standards, and stay competitive in today’s fast-paced market.