Table of Contents

Advantages of Using High Carbon Wire Drawing Machine in Manufacturing Processes

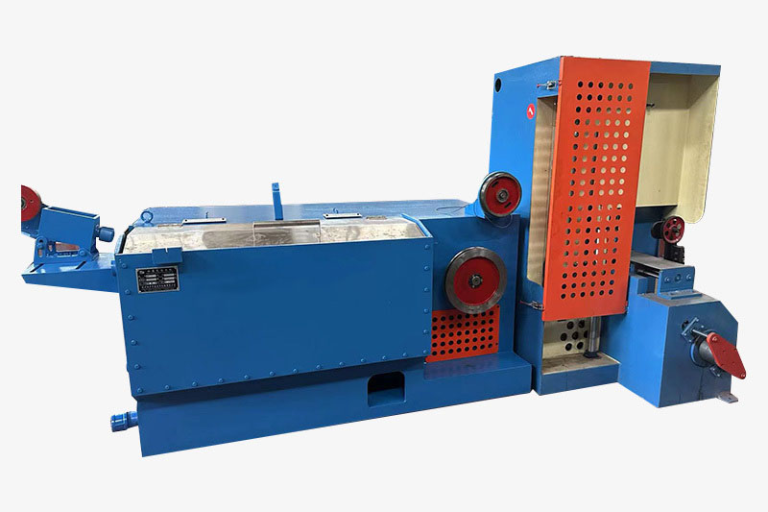

High carbon wire drawing machines are essential tools in the manufacturing industry, particularly in the production of high-quality wires used in various applications. These machines are designed to draw wire through a series of dies to reduce its diameter and improve its quality. The use of high carbon wire drawing machines offers several advantages that make them indispensable in manufacturing processes.

One of the key advantages of using high carbon wire drawing machines is the ability to produce wires with precise dimensions. These machines are equipped with multiple dies that can be adjusted to achieve the desired diameter of the wire. This level of precision is crucial in industries where the quality of the wire is paramount, such as in the production of automotive parts or electronic components.

In addition to producing wires with precise dimensions, high carbon wire drawing machines also offer the advantage of improving the surface finish of the wire. As the wire is drawn through the dies, any imperfections on the surface are smoothed out, resulting in a clean and polished finish. This is important in applications where the appearance of the wire is important, such as in jewelry making or architectural design.

Another advantage of using high carbon wire drawing machines is the ability to increase the strength of the wire. By drawing the wire through a series of dies, the metal grains are elongated and aligned in the direction of the wire, resulting in a stronger and more durable product. This is particularly beneficial in industries where the wire is subjected to high levels of stress or tension, such as in the construction or aerospace industries.

Furthermore, high carbon wire drawing machines offer the advantage of increasing the ductility of the wire. Ductility refers to the ability of a material to deform without breaking, and is an important property in applications where the wire needs to be bent or shaped. By drawing the wire through the dies, its ductility is improved, making it easier to work with and reducing the risk of breakage during manufacturing processes.

Additionally, high carbon wire drawing machines are highly efficient and cost-effective. These machines are designed to operate at high speeds, allowing for the rapid production of large quantities of wire. This efficiency not only reduces production time but also lowers manufacturing costs, making high carbon wire drawing machines a valuable investment for businesses looking to improve their bottom line.

In conclusion, the advantages of using high carbon wire drawing machines in manufacturing processes are numerous. From producing wires with precise dimensions and improved surface finish to increasing strength and ductility, these machines offer a range of benefits that make them indispensable in a variety of industries. With their efficiency and cost-effectiveness, high carbon wire drawing machines are a valuable tool for businesses looking to enhance the quality and performance of their products.

Tips for Maintaining and Optimizing Performance of High Carbon Wire Drawing Machine

High carbon wire drawing machines are essential equipment in the manufacturing industry, used to produce high-quality wire products for various applications. To ensure the optimal performance and longevity of these machines, proper maintenance and care are crucial. In this article, we will discuss some tips for maintaining and optimizing the performance of high carbon wire drawing machines.

Regular cleaning and lubrication are key aspects of maintaining a high carbon wire drawing machine. Dust, dirt, and debris can accumulate on the machine’s components, leading to increased friction and wear. Regularly cleaning the machine with a soft brush or cloth can help prevent these issues. Additionally, lubricating the moving parts of the machine with a high-quality lubricant can reduce friction and ensure smooth operation.

Inspecting the machine for any signs of wear or damage is also important. Check the machine’s components, such as the drawing dies, capstans, and bearings, for any signs of wear or damage. Replace any worn or damaged parts immediately to prevent further damage to the machine and ensure optimal performance.

Calibrating the machine regularly is another crucial aspect of maintaining its performance. Proper calibration ensures that the machine is operating at its optimal settings, producing high-quality wire products consistently. Consult the manufacturer’s guidelines for the recommended calibration schedule and procedures for your specific machine.

Monitoring the machine’s performance and output is essential for identifying any potential issues early on. Keep track of the machine’s production output, quality of the wire products, and any unusual noises or vibrations during operation. Any deviations from the normal operating conditions should be investigated and addressed promptly to prevent further damage to the machine.

Training your operators on the proper use and maintenance of the high carbon wire drawing machine is also important. Ensure that your operators are familiar with the machine’s operation, safety procedures, and maintenance requirements. Providing regular training and refresher courses can help prevent operator errors and ensure the machine’s optimal performance.

Investing in quality spare parts and components for your high carbon wire drawing machine is crucial for maintaining its performance. Using genuine spare parts from the manufacturer can ensure compatibility and reliability, preventing potential issues that may arise from using inferior or counterfeit parts.

Lastly, scheduling regular maintenance checks and servicing by qualified technicians can help prolong the life of your high carbon wire drawing machine. Professional technicians can identify and address any potential issues before they escalate, ensuring the machine’s optimal performance and minimizing downtime.

In conclusion, proper maintenance and care are essential for maintaining and optimizing the performance of high carbon wire drawing machines. By following these tips, you can ensure that your machine operates at its best, producing high-quality wire products consistently. Remember to clean and lubricate the machine regularly, inspect for wear or damage, calibrate the machine, monitor its performance, train your operators, use quality spare parts, and schedule regular maintenance checks. By taking these steps, you can maximize the efficiency and longevity of your high carbon wire drawing machine.