Table of Contents

Exploring the Benefits of Using Flat Wire Precision Layer Winding Machines in Manufacturing Processes

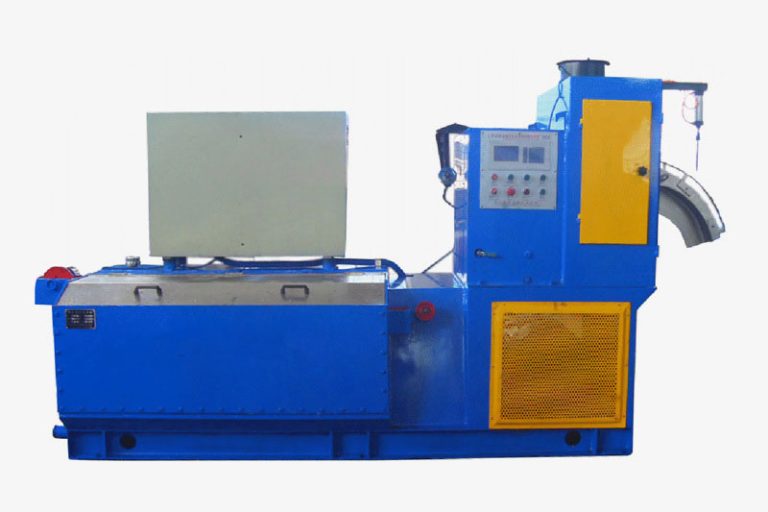

Flat wire precision layer winding machine are an essential tool in the manufacturing industry, offering a wide range of benefits that can significantly improve production processes. These machines are designed to wind flat wire onto spools or bobbins with precision and accuracy, ensuring that the wire is evenly distributed and tightly wound. In this article, we will explore the various benefits of using flat wire precision layer winding machines in manufacturing processes.

One of the key advantages of using flat wire precision layer winding machines is their ability to increase efficiency and productivity. These machines are capable of winding wire at high speeds, allowing manufacturers to produce more products in a shorter amount of time. This can help companies meet tight deadlines and fulfill customer orders quickly and efficiently.

In addition to improving efficiency, flat wire precision layer winding machines also help to reduce waste and minimize errors in the manufacturing process. By ensuring that the wire is wound evenly and tightly, these machines can help to prevent tangling, knotting, and other issues that can lead to wasted materials and production delays. This can ultimately save manufacturers time and money, as well as improve the overall quality of their products.

Another benefit of using Flat Wire Or Cable Precision Layer Winding Machine is their versatility. These machines are capable of winding a wide range of wire sizes and materials, making them suitable for a variety of manufacturing applications. Whether you are working with copper, aluminum, steel, or other materials, a flat wire precision layer winding machine can help you achieve consistent and reliable results.

Furthermore, flat wire precision layer winding machines are easy to operate and maintain, making them a cost-effective solution for manufacturers of all sizes. These machines are designed to be user-friendly, with intuitive controls and settings that allow operators to quickly set up and adjust the winding process. Additionally, flat wire precision layer winding machines are built to last, with durable components that can withstand the rigors of daily use in a manufacturing environment.

Overall, flat wire precision layer winding machines offer a wide range of benefits that can help manufacturers improve efficiency, reduce waste, and enhance the quality of their products. By investing in one of these machines, companies can streamline their production processes, increase productivity, and ultimately achieve greater success in the competitive manufacturing industry.

In conclusion, flat wire precision layer winding machines are an invaluable tool for manufacturers looking to optimize their production processes. With their ability to increase efficiency, reduce waste, and improve quality, these machines offer a wide range of benefits that can help companies achieve their manufacturing goals. Whether you are producing electrical components, automotive parts, or other products that require precision winding, a flat wire precision layer winding machine can help you achieve consistent and reliable results.

How to Choose the Right Flat Wire Precision Layer Winding Machine for Your Factory

Flat Welding Wire Precision Layer Semi-Automatic Winding Machine is essential equipment for factories that produce coils, transformers, and other electrical components. These machines are designed to wind flat wire onto spools or bobbins with precision and accuracy, ensuring that the final product meets the required specifications. Choosing the right flat wire precision layer winding machine for your factory is crucial to ensure efficient production and high-quality output.

When selecting a flat wire precision layer winding machine, there are several factors to consider. The first consideration is the type of flat wire that will be used in the winding process. Flat wires come in various materials, sizes, and shapes, so it is important to choose a machine that is compatible with the specific type of flat wire that your factory will be using.

Another important factor to consider is the speed and capacity of the winding machine. The speed of the machine will determine how quickly coils can be wound, while the capacity will determine the maximum size of the coils that can be produced. It is important to choose a machine that can meet the production requirements of your factory without sacrificing quality.

Additionally, the precision and accuracy of the winding machine are crucial factors to consider. A high-quality winding machine will ensure that each coil is wound with consistent tension and alignment, resulting in a finished product that meets the required specifications. Look for machines that offer features such as automatic tension control and programmable winding patterns to ensure precise winding every time.

Durability and reliability are also important considerations when choosing a flat wire precision layer winding machine. Look for machines that are built with high-quality materials and components that can withstand the rigors of continuous use in a factory setting. Additionally, choose a machine from a reputable manufacturer that offers reliable customer support and service to ensure that any issues can be quickly resolved.

Cost is another important factor to consider when choosing a flat wire precision layer winding machine for your factory. While it may be tempting to opt for a cheaper machine to save money upfront, investing in a high-quality machine will pay off in the long run with increased efficiency and productivity. Consider the total cost of ownership, including maintenance and operating costs, when making your decision.

In conclusion, choosing the right flat wire precision layer winding machine for your factory is essential to ensure efficient production and high-quality output. Consider factors such as the type of flat wire, speed and capacity, precision and accuracy, durability and reliability, and cost when making your decision. By selecting a machine that meets your specific requirements and offers the features you need, you can ensure that your factory operates smoothly and produces coils and transformers that meet the highest standards of quality.