Table of Contents

Cómo elegir el descalcificador de pulido de banda de lijado adecuado para su proyecto

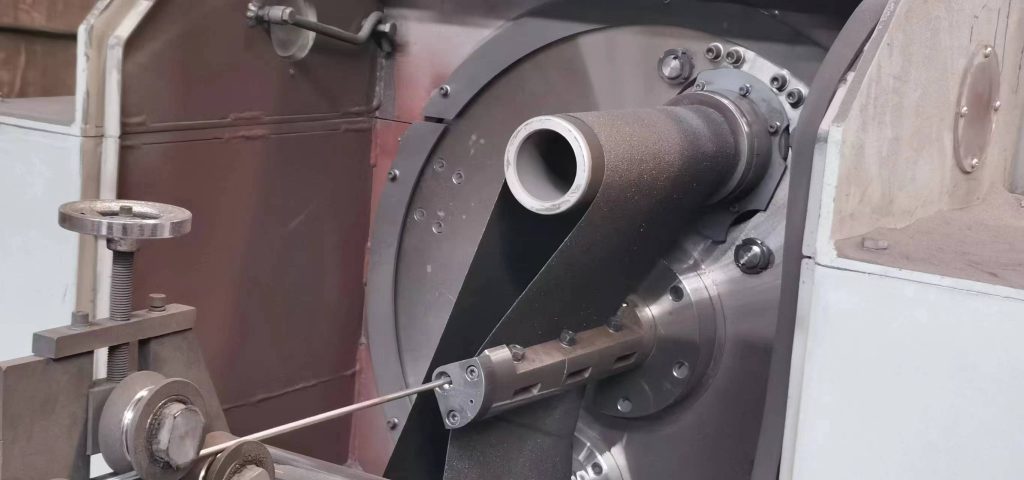

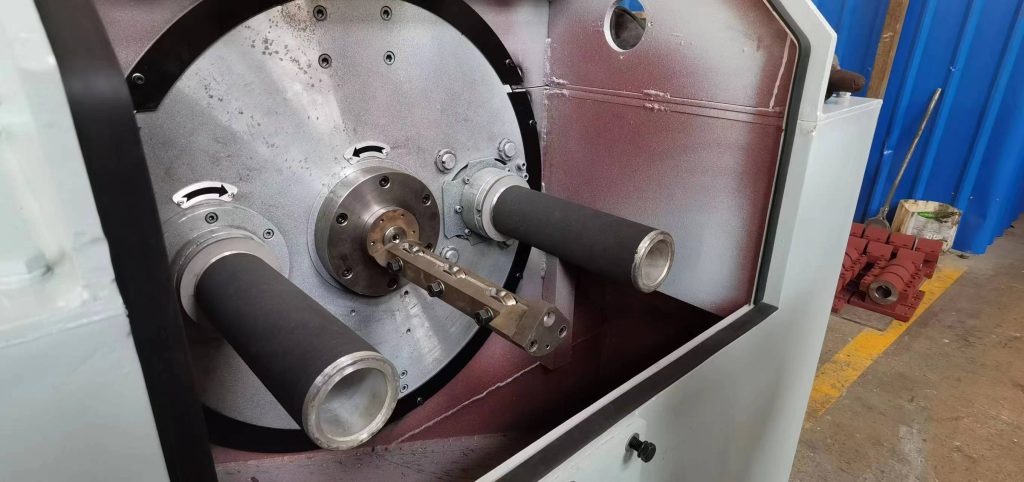

Cuando se trata de trabajar metales, tener las herramientas adecuadas para el trabajo es esencial. Una herramienta que se usa comúnmente en la fabricación de metales es un desincrustador de pulido con cinta de arena. Esta herramienta se utiliza para eliminar óxido, pintura y otras imperfecciones de las superficies metálicas, dejándolas suaves y listas para su posterior procesamiento.

Hay muchos tipos diferentes de descalcificadores para rectificado con banda de lijado disponibles en el mercado, cada uno con sus propias características y capacidades únicas. Elegir el descalcificador adecuado para su proyecto puede ser una tarea desalentadora, pero con algunos conocimientos básicos y comprensión de las diferentes opciones disponibles, puede tomar una decisión informada que le ayudará a lograr los mejores resultados.

Una de las primeras cosas a considerar A la hora de elegir una máquina desincrustadora mecánica con cinta de arena, está el tipo de metal con el que trabajará. Los diferentes metales tienen diferentes niveles de dureza y características de superficie, por lo que es importante elegir un descalcificador que esté diseñado específicamente para el tipo de metal con el que trabajará. Por ejemplo, si trabaja con acero inoxidable, necesitará un descalcificador que sea capaz de eliminar revestimientos superficiales resistentes sin dañar el metal subyacente.

Otro factor importante a considerar es el tamaño y la forma de las superficies metálicas en las que trabajará. con. Algunos descalcificadores están diseñados para usarse en superficies planas, mientras que otros son más adecuados para superficies curvas o irregulares. Es importante elegir un descalcificador que sea compatible con la forma de las superficies metálicas con las que trabajará para garantizar un acabado liso y uniforme.

Además de considerar el tipo de metal y la forma de las superficies que va a trabajar, también es importante considerar el tamaño y potencia del descalcificador. Los descalcificadores más grandes son capaces de eliminar imperfecciones de la superficie de manera más rápida y eficiente, lo que los hace ideales para proyectos más grandes o aplicaciones industriales. Sin embargo, los descalcificadores más pequeños pueden ser más adecuados para proyectos más pequeños o para uso en espacios reducidos donde un descalcificador más grande sería difícil de maniobrar.

Al elegir un desincrustante para lijado de banda de lijado, también es importante considerar el tamaño de grano de la banda de lijado. El tamaño de grano se refiere al grosor del material abrasivo en la banda de lijado, donde los números de grano más bajos indican un material abrasivo más grueso y los números de grano más altos indican un material abrasivo más fino. Los tamaños de grano más gruesos se usan generalmente para eliminar imperfecciones superficiales importantes, mientras que los tamaños de grano más finos se usan para lograr un acabado suave y pulido.

Finalmente, es importante considerar la calidad y durabilidad del descalcificador. Invertir en un descalcificador de alta calidad diseñado para durar le ahorrará tiempo y dinero a largo plazo, ya que no tendrá que reemplazarlo con tanta frecuencia. Busque descalcificadores que estén fabricados con materiales duraderos y que tengan reputación de confiabilidad y rendimiento.

En conclusión, elegir el descalcificador de banda de lijado adecuado para su proyecto es esencial para lograr los mejores resultados. Considere el tipo de metal con el que trabajará, el tamaño y la forma de las superficies en las que trabajará, el tamaño y potencia del descalcificador, el tamaño de grano de la banda de lijado y la calidad y durabilidad del descalcificador. Al tener en cuenta estos factores, podrá tomar una decisión informada que le ayudará a lograr un acabado suave y profesional en sus superficies metálicas.

Consejos para utilizar correctamente el desincrustante para esmerilado de banda de lijado

Los descalcificadores de cinta de lijado son herramientas esenciales para eliminar óxido, pintura y otras imperfecciones de las superficies metálicas. Cuando se usan correctamente, estas herramientas pueden ayudarlo a lograr un acabado suave y pulido en su pieza de trabajo. Sin embargo, el uso inadecuado de un desincrustante para esmerilado con banda de lijado puede provocar daños a la pieza de trabajo o lesiones al usuario. En este artículo, le brindaremos algunos consejos para utilizar correctamente un desincrustante de lijado para garantizar resultados seguros y efectivos.

En primer lugar, es importante elegir la banda de lijado adecuada para el trabajo. Hay disponibles diferentes granos de cintas de lijado, desde grueso hasta fino. El grano de la banda de lijado que elija dependerá del nivel de imperfecciones de la superficie que necesite eliminar. Los granos gruesos son adecuados para el pulido intensivo y la eliminación de capas gruesas de pintura u óxido, mientras que los granos finos son ideales para terminar y pulir la superficie. Asegúrese de seleccionar el grano adecuado para su aplicación específica para lograr los mejores resultados.

Antes de utilizar el desincrustante para esmerilado con banda de lijado, es fundamental inspeccionar la herramienta para detectar cualquier signo de daño o desgaste. Revise la banda de lijado en busca de roturas, deshilachados u otros defectos que puedan afectar su rendimiento. Reemplace las bandas de lijado dañadas antes de usar la herramienta para evitar accidentes o daños a la pieza de trabajo. Además, asegúrese de que la herramienta esté correctamente asegurada y estable antes de comenzar el proceso de rectificado para evitar contratiempos.

Cuando utilice un desincrustante de rectificado con banda de lijado, es importante mantener una presión y velocidad constantes mientras mueve la herramienta a lo largo de la pieza de trabajo. Aplicar demasiada presión puede hacer que la banda de lijado se desgaste rápidamente y provocar un pulido desigual, mientras que muy poca presión puede no eliminar eficazmente las imperfecciones de la superficie. De manera similar, mover la herramienta demasiado rápido o demasiado lento puede afectar la calidad del acabado. Encuentre un equilibrio entre presión y velocidad que permita que la banda de lijado funcione de manera eficiente sin causar daños a la pieza de trabajo.

También es esencial mantener el área de trabajo limpia y libre de residuos mientras utiliza un desincrustante para lijado de banda de lijado. Se pueden acumular polvo y residuos en la pieza de trabajo y la herramienta, afectando el rendimiento de la banda de lijado y potencialmente causando daños. Utilice una aspiradora o un recolector de polvo para eliminar los desechos mientras trabaja para mantener un ambiente de trabajo limpio. Además, use equipo de protección personal adecuado, como gafas de seguridad y una máscara contra el polvo, para protegerse de partículas y desechos en el aire.

Después de usar el desincrustante para esmerilado con banda de lijado, es importante limpiar y mantener la herramienta adecuadamente para garantizar su longevidad. y rendimiento. Retire el polvo o los residuos de la herramienta y de la banda de lijado, y guarde la herramienta en un lugar seco y seguro. Inspeccione periódicamente la herramienta para detectar signos de desgaste o daño y reemplace las piezas desgastadas según sea necesario. Al mantener adecuadamente su desincrustante para esmerilado con banda de lijado, puede asegurarse de que continúe brindándole resultados confiables y efectivos.

En conclusión, el uso de un desincrustante para esmerilado con banda de lijado requiere atención al detalle y una técnica adecuada para lograr los resultados deseados. Si sigue estos consejos para utilizar correctamente un desincrustante para esmerilado con banda de lijado, podrá garantizar un esmerilado seguro y eficaz de superficies metálicas. Recuerde elegir el grano de banda de lijado adecuado, inspeccionar la herramienta en busca de daños, mantener una presión y velocidad constantes, mantener limpia el área de trabajo y limpiar y mantener la herramienta después de su uso. Con estas pautas en mente, podrá lograr un acabado liso y pulido en su pieza de trabajo con facilidad.