Table of Contents

Consejos para maximizar la eficiencia al utilizar un descalcificador para esmerilado con banda de lijado

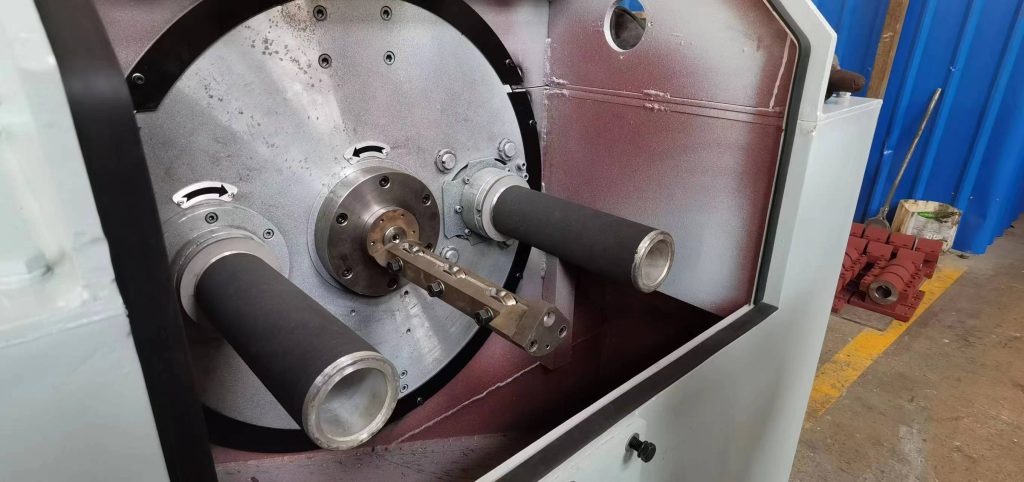

Cuando se trata de fabricación y acabado de metales, los desincrustantes para esmerilado con banda de lijado son herramientas esenciales para lograr una superficie lisa y pulida. Sin embargo, para maximizar la eficiencia y obtener los mejores resultados, es importante seguir algunos consejos y técnicas clave. En este artículo, analizaremos algunas estrategias para utilizar eficazmente una máquina desincrustadora mecánica con cinta de arena.

En primer lugar, es fundamental elegir la banda de lijado adecuada para el trabajo. Hay diferentes granos y materiales disponibles, cada uno adecuado para aplicaciones específicas. Para desincrustaciones y pulidos de alta resistencia, se recomienda una banda de lijado de grano grueso, mientras que un grano más fino es más adecuado para acabado y pulido. Al seleccionar la banda de lijado adecuada, puede asegurarse de que el proceso de descalcificación sea eficiente y efectivo.

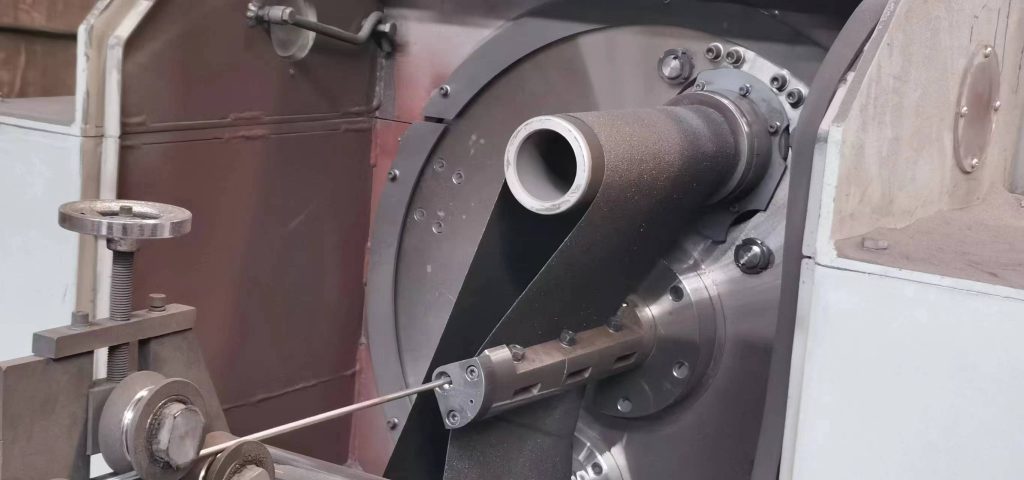

Además de elegir la banda de lijado adecuada, es importante configurar y ajustar correctamente el descalcificador para un rendimiento óptimo. Asegúrese de que la correa esté correctamente tensada y alineada correctamente con la pieza de trabajo. Esto evitará el deslizamiento y garantizará que el proceso de descalcificación sea uniforme y consistente. Además, verifique los ajustes de velocidad y presión en el desincrustador para asegurarse de que sean apropiados para el material en el que se está trabajando.

Otro consejo clave para maximizar la eficiencia al usar un desincrustador de pulido con banda de lijado es mantener una velocidad de avance constante y constante. Evite empujar o tirar de la pieza de trabajo demasiado rápido, ya que esto puede provocar una descalcificación desigual y un desgaste prematuro de la banda de lijado. En su lugar, alimente la pieza de trabajo a través del descalcificador a un ritmo constante, permitiendo que la banda abrasiva elimine el material de manera uniforme y eficiente.

Además, es importante inspeccionar y limpiar periódicamente el descalcificador de la banda de lijado para garantizar un rendimiento óptimo. Con el tiempo, el polvo, los residuos y las partículas metálicas pueden acumularse en la correa, reduciendo su eficacia y provocando un desgaste prematuro. Limpie periódicamente el descalcificador con un cepillo o aire comprimido para eliminar cualquier acumulación y prolongar la vida útil de la banda de lijado.

Además, considere usar un lubricante o refrigerante al descalcificar con una máquina descalcificadora de banda de lijado. Esto puede ayudar a reducir la fricción y la acumulación de calor, lo que resulta en una descalcificación más suave y bandas de lijado más duraderas. Asegúrese de utilizar un lubricante que sea compatible con el material sobre el que se está trabajando y siga las recomendaciones del fabricante para su aplicación.

Finalmente, tome las precauciones de seguridad adecuadas cuando utilice un desincrustante para esmerilado con banda de lijado. Utilice equipo de protección personal adecuado, como gafas y guantes de seguridad, para protegerse de desechos voladores y partículas abrasivas. Además, tenga en cuenta su entorno y mantenga las manos y los dedos alejados de las partes móviles del descalcificador.

En conclusión, si sigue estos consejos y técnicas, puede maximizar la eficiencia al utilizar un descalcificador con banda de lijado. Elija la banda de lijado adecuada, configure y ajuste el descalcificador adecuadamente, mantenga una velocidad de alimentación constante, limpie e inspeccione el descalcificador con regularidad, use lubricantes o refrigerantes según sea necesario y practique las precauciones de seguridad adecuadas. Al incorporar estas estrategias en su proceso de desincrustación, podrá lograr superficies lisas y pulidas con el mínimo esfuerzo y la máxima eficiencia.

Beneficios de utilizar un descalcificador eficiente para el rectificado de cintas de lijado en la fabricación de metales

Los descalcificadores de pulido con banda de lijado eficientes son herramientas esenciales en la industria de fabricación de metales. Estas máquinas están diseñadas para eliminar imperfecciones, óxido y escamas de las superficies metálicas, dejando un acabado suave y limpio. Al utilizar un descalcificador de pulido con banda de lijado, los fabricantes de metales pueden ahorrar tiempo y esfuerzo y, al mismo tiempo, lograr resultados de alta calidad.

Uno de los beneficios clave de usar un descalcificador de pulido de banda de arena eficiente es su capacidad para eliminar rápida y eficazmente las imperfecciones de las superficies metálicas. . Ya sea que trabajen con acero, aluminio u otros metales, estas máquinas pueden eliminar fácilmente el óxido, las incrustaciones y otros contaminantes, dejando una superficie limpia y lisa. Esto no sólo mejora la apariencia del metal sino que también garantiza que esté listo para su posterior procesamiento o acabado.

Además de mejorar la apariencia de las superficies metálicas, los descalcificadores eficientes para el pulido con banda de lijado también ayudan a mejorar la calidad general del producto terminado. Al eliminar las imperfecciones de la superficie, estas máquinas garantizan que el metal esté libre de defectos que podrían comprometer su integridad estructural o su rendimiento. Esto es especialmente importante en industrias donde la precisión y la calidad son primordiales, como la aeroespacial, la automotriz y la construcción.

Otro beneficio de utilizar un descalcificador de pulido con banda de lijado eficiente es el ahorro de tiempo y mano de obra que proporciona. Estas máquinas están diseñadas para funcionar de forma rápida y eficiente, lo que permite a los fabricantes de metales completar su trabajo en menos tiempo que los métodos tradicionales. Esto no solo aumenta la productividad sino que también reduce los costos de mano de obra, lo que la convierte en una solución rentable para las empresas de fabricación de metales.

Además, los descalcificadores de pulido con banda de lijado eficientes son herramientas versátiles que se pueden usar en una amplia gama de superficies metálicas. Ya sea que trabajen con láminas planas, tubos o formas complejas, estas máquinas pueden adaptarse fácilmente a diferentes superficies y contornos, garantizando un acabado uniforme en todas las piezas. Esta versatilidad los convierte en un activo valioso en cualquier taller de fabricación de metales.

Además, los descalcificadores de pulido con banda de lijado eficientes son fáciles de operar y mantener, lo que los hace ideales tanto para fabricantes de metales experimentados como para principiantes. Con controles simples y requisitos mínimos de configuración, estas máquinas se pueden integrar rápidamente en cualquier flujo de trabajo, lo que permite a los fabricantes comenzar a usarlas de inmediato. Y con mantenimiento y cuidado regulares, estas máquinas pueden brindar años de servicio confiable, lo que las convierte en una inversión inteligente para cualquier negocio de fabricación de metales.

En conclusión, los descalcificadores eficientes para rectificado con banda de lijado ofrecen una amplia gama de beneficios para los fabricantes de metales. Desde mejorar la apariencia y calidad de las superficies metálicas hasta ahorrar tiempo y costos de mano de obra, estas máquinas son herramientas esenciales en la industria de fabricación de metales. Con su versatilidad, facilidad de uso y bajos requisitos de mantenimiento, los descalcificadores de molienda con banda de lijado eficientes son un activo valioso para cualquier taller de fabricación de metales que busque lograr resultados de alta calidad de manera eficiente.