Table of Contents

How to Choose the Right Sanding Belt for Your Grinding Machine

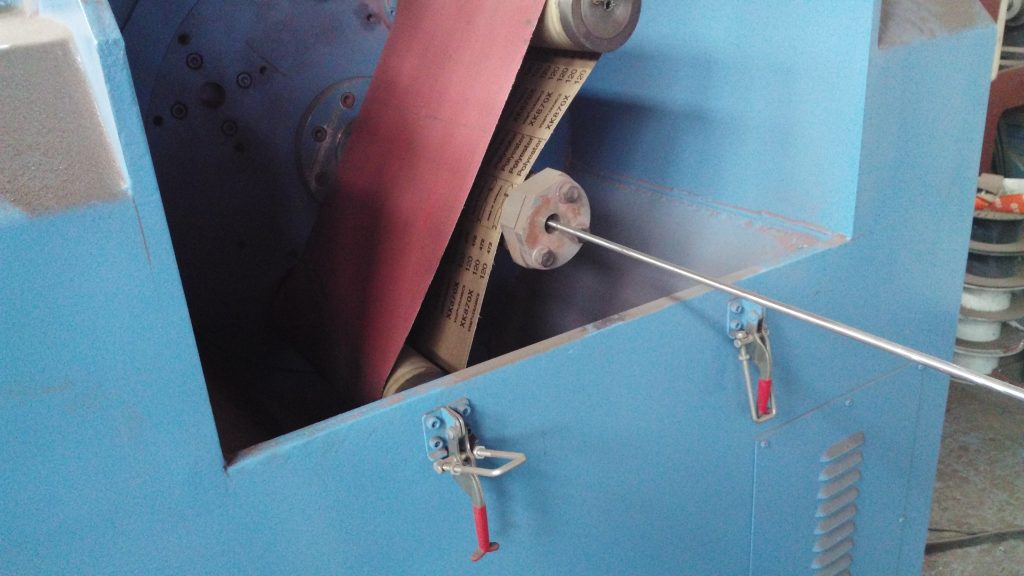

When it comes to using a Sanding Belt Grinding Descaler, choosing the right sanding belt is crucial for achieving the best results. The sanding belt is a key component of the machine that determines the quality of the finish on your workpiece. With so many options available on the market, it can be overwhelming to select the right sanding belt for your specific needs. In this article, we will discuss some important factors to consider when choosing a sanding belt for your grinding machine.

One of the first things to consider when choosing a sanding belt is the material of the workpiece you will be grinding. Different materials require different types of sanding belts to achieve the desired finish. For example, if you are working with metal, you will need a sanding belt that is specifically designed for metal grinding. On the other hand, if you are working with wood, you will need a sanding belt that is suitable for wood grinding. It is important to match the material of the sanding belt to the material of the workpiece to ensure optimal results.

Another important factor to consider when choosing a sanding belt is the grit size. The grit size of a sanding belt refers to the coarseness or fineness of the abrasive particles on the belt. A lower grit size indicates a coarser abrasive, while a higher grit size indicates a finer abrasive. The grit size you choose will depend on the level of material removal and finish quality you desire. For heavy material removal, a lower grit size is recommended, while for fine finishing work, a higher grit size is preferred.

In addition to material and grit size, it is also important to consider the backing material of the sanding belt. The backing material provides support to the abrasive particles and helps to maintain the shape and integrity of the belt during use. Common backing materials include cloth, paper, and polyester. Cloth-backed sanding belts are durable and flexible, making them ideal for heavy-duty grinding applications. Paper-backed sanding belts are more flexible and conformable, making them suitable for contour sanding. Polyester-backed Sand Belt Grinding Descaler are tear-resistant and long-lasting, making them a good choice for high-speed grinding.

Furthermore, it is important to consider the type of abrasive material used on the sanding belt. Common abrasive materials include aluminum oxide, silicon carbide, and zirconia alumina. Aluminum oxide is a versatile abrasive that is suitable for a wide range of materials and applications. Silicon carbide is a sharp abrasive that is ideal for hard and brittle materials. Zirconia alumina is a durable abrasive that is well-suited for heavy material removal.

In conclusion, choosing the right sanding belt for your grinding machine is essential for achieving the best results. Consider factors such as material, grit size, backing material, and abrasive material when selecting a sanding belt for your specific needs. By taking the time to choose the right sanding belt, you can ensure that your grinding machine performs at its best and produces high-quality finishes on your workpieces.

Maintenance Tips for Extending the Lifespan of Your Sanding Belt Grinding Machine

Sanding belt grinding machines are essential tools in many industries, used for shaping and finishing various materials. To ensure the longevity and efficiency of your sanding belt grinding machine, proper maintenance is crucial. By following a few simple tips, you can extend the lifespan of your machine and keep it running smoothly for years to come.

One of the most important maintenance tasks for your wire descaler belt grinding machine is regular cleaning. Dust and debris can build up on the machine over time, causing it to run less efficiently and potentially damaging the belts. To prevent this, make sure to clean the machine after each use. Use a brush or vacuum to remove any dust and debris from the machine’s surfaces, belts, and rollers.

In addition to regular cleaning, it is important to inspect the machine for any signs of wear or damage. Check the belts for any tears or fraying, and replace them as needed. Inspect the rollers and bearings for any signs of wear, and lubricate them regularly to keep them running smoothly. By catching and addressing any issues early on, you can prevent more serious damage to the machine and extend its lifespan.

Another important maintenance task for your sanding belt grinding machine is proper tensioning of the belts. Belts that are too loose can slip or wear unevenly, while belts that are too tight can put unnecessary strain on the machine’s motor and bearings. Make sure to follow the manufacturer’s guidelines for tensioning the belts, and adjust them as needed to ensure they are running smoothly and evenly.

In addition to regular cleaning and inspection, it is important to keep your sanding belt grinding machine properly calibrated. Over time, the machine’s settings can drift, leading to less precise results and potentially damaging the materials being worked on. Make sure to regularly check and adjust the machine’s settings, such as belt speed and pressure, to ensure they are set correctly for the materials being worked on.

Finally, it is important to store your sanding belt grinding machine properly when not in use. Make sure to keep it in a clean, dry environment away from dust and debris. Cover the machine when not in use to protect it from damage, and make sure to follow any specific storage guidelines provided by the manufacturer.

In conclusion, proper maintenance is essential for extending the lifespan of your sanding belt grinding machine. By following these tips, you can keep your machine running smoothly and efficiently for years to come. Regular cleaning, inspection, tensioning, calibration, and storage are all important tasks to keep your machine in top condition. By taking care of your machine, you can ensure that it continues to provide high-quality results for all your grinding needs.