Table of Contents

Maintenance Tips for Smooth Steel Straightening and Cutting Machines

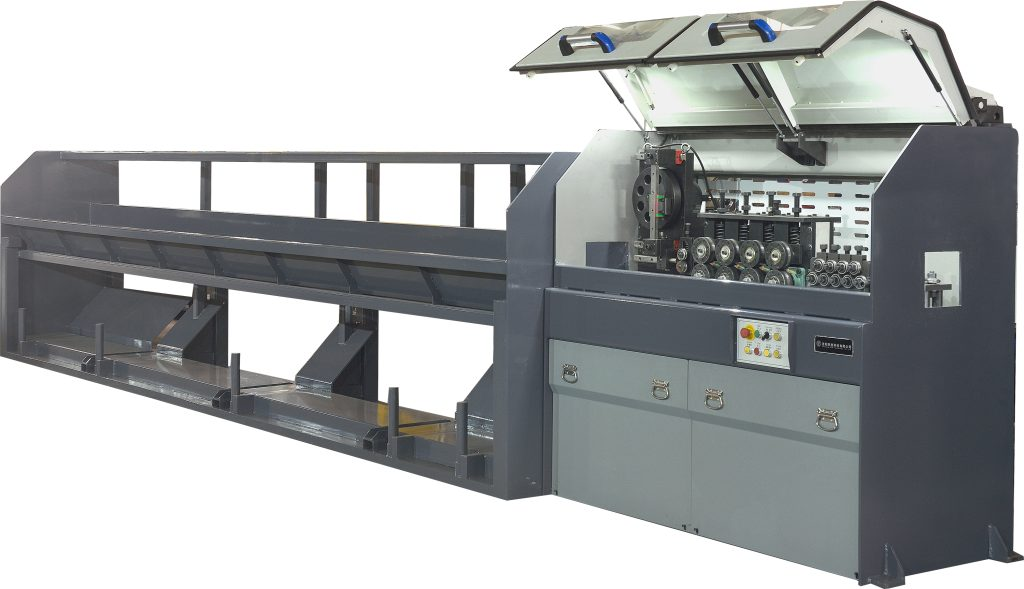

Steel Wire Straightening and Cutting Machines are essential tools in the construction and manufacturing industries. These machines are used to straighten and cut steel bars with precision and efficiency. To ensure that these machines operate smoothly and efficiently, proper maintenance is crucial. In this article, we will discuss some maintenance tips for smooth steel straightening and cutting machines.

One of the most important maintenance tasks for steel straightening and cutting machines is regular cleaning. Dust, dirt, and debris can accumulate on the machine’s components, leading to decreased performance and potential damage. It is important to clean the machine regularly using a soft brush or cloth to remove any buildup. Additionally, lubricating the moving parts of the machine with a suitable lubricant will help prevent wear and tear and ensure smooth operation.

Another important maintenance tip is to regularly inspect the machine for any signs of wear or damage. Check the cutting blades, rollers, and other components for any signs of wear and tear. Replace any damaged or worn parts immediately to prevent further damage to the machine. It is also important to check the machine’s alignment regularly to ensure that it is operating correctly.

In addition to regular cleaning and inspection, it is important to follow the manufacturer’s recommended maintenance schedule for the machine. This may include tasks such as replacing filters, adjusting tension settings, and calibrating the machine. By following the manufacturer’s guidelines, you can ensure that your steel straightening and cutting machine operates at its best.

Proper storage of the machine is also important for maintaining its performance. Store the machine in a clean, dry environment away from moisture and extreme temperatures. Cover the machine when not in use to protect it from dust and debris. Additionally, it is important to follow proper shutdown procedures when turning off the machine to prevent damage to its components.

Regularly calibrating the machine is another important maintenance task. Calibration ensures that the machine is cutting and straightening steel bars accurately and efficiently. Follow the manufacturer’s guidelines for calibrating the machine and make any necessary adjustments to ensure optimal performance.

In conclusion, proper maintenance is essential for ensuring the smooth operation of steel Straightening And Cutting Machine For Steel Bar. By following these maintenance tips, you can prolong the life of your machine and ensure that it operates at its best. Regular cleaning, inspection, lubrication, and calibration are all important tasks that will help keep your machine in top condition. Remember to follow the manufacturer’s guidelines for maintenance and storage to ensure that your machine continues to perform efficiently for years to come.

Advantages of Using Smooth Steel Straightening and Cutting Machines

Smooth steel straightening and cutting machines are essential tools in the metalworking industry. These machines are designed to efficiently straighten and cut steel bars, rods, and wires with precision and accuracy. In this article, we will discuss the advantages of using smooth steel straightening and cutting machines in various applications.

One of the main advantages of using smooth steel straightening and cutting machines is their ability to increase productivity. These machines are capable of straightening and cutting steel at a much faster rate than manual methods, saving time and labor costs. This increased efficiency allows for higher production output and faster turnaround times, making them ideal for high-volume manufacturing operations.

In addition to improving productivity, Automatic Wire Straightening and Cutting Machine also ensure consistent quality. These machines are equipped with advanced technology that allows for precise straightening and cutting of steel, resulting in uniform and accurate finished products. This consistency is crucial in industries where quality control is paramount, such as construction, automotive, and aerospace.

Furthermore, smooth steel straightening and cutting machines are versatile tools that can handle a wide range of steel sizes and shapes. Whether you are working with round bars, square rods, or irregularly shaped wires, these machines can be easily adjusted to accommodate different materials. This versatility makes them suitable for a variety of applications, from small-scale workshops to large-scale manufacturing plants.

Another advantage of using smooth steel straightening and cutting machines is their safety features. These machines are designed with safety in mind, with built-in guards and sensors to prevent accidents and injuries. Operators can work with peace of mind knowing that they are protected from potential hazards, such as flying debris or sharp edges.

Moreover, smooth steel straightening and cutting machines are user-friendly and easy to operate. They are equipped with intuitive controls and settings that allow operators to adjust parameters quickly and efficiently. Training requirements are minimal, making it easy for new operators to learn how to use these machines effectively.

Additionally, smooth steel straightening and cutting machines are cost-effective investments for businesses. While the initial upfront cost may be higher than manual methods, the long-term benefits far outweigh the initial investment. These machines require minimal maintenance and have a long lifespan, reducing downtime and repair costs in the long run.

In conclusion, smooth steel straightening and cutting machines offer numerous advantages for businesses in the metalworking industry. From increased productivity and consistent quality to versatility and safety features, these machines are essential tools for any operation that works with steel materials. Investing in a smooth steel straightening and cutting machine can help businesses streamline their production processes, improve efficiency, and ultimately, increase profitability.