Table of Contents

Maintenance Tips for Keeping Your Copper Wire Drawing Machine in Top Condition

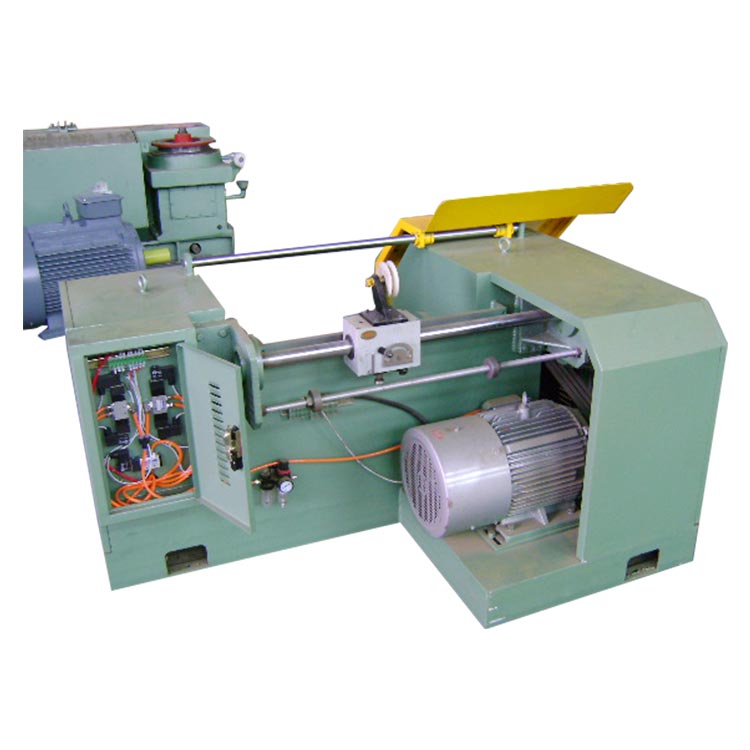

Wet Wire Drawing Machine is essential equipment in the manufacturing industry, used to produce high-quality copper wires of various sizes and gauges. To ensure the efficient operation of your copper wire drawing machine and maintain its top condition, regular maintenance is crucial. Proper maintenance not only extends the lifespan of the machine but also ensures consistent performance and high-quality output.

One of the key maintenance tips for keeping your copper wire drawing machine in top condition is to regularly inspect and clean the machine. Dust, dirt, and debris can accumulate on the machine’s components, leading to decreased efficiency and potential damage. Regularly cleaning the machine with a soft brush or cloth can help prevent build-up and ensure smooth operation.

In addition to cleaning, it is important to lubricate the moving parts of the copper wire drawing machine. Proper lubrication reduces friction, wear, and tear on the machine’s components, prolonging its lifespan and ensuring optimal performance. Be sure to use the recommended lubricants and follow the manufacturer’s guidelines for lubrication intervals.

Another important maintenance tip is to regularly check and replace worn or damaged parts. Over time, the components of the copper wire drawing machine can wear out or become damaged, affecting the machine’s performance. Inspect the machine regularly for signs of wear or damage, such as frayed wires, worn pulleys, or loose bolts, and replace any faulty parts promptly to prevent further damage.

Furthermore, it is essential to monitor the tension and alignment of the wire drawing machine. Improper tension or misalignment can lead to uneven wire drawing, poor quality output, and potential damage to the machine. Regularly check the tension of the wires and adjust as needed to ensure smooth operation. Additionally, ensure that the machine’s components are properly aligned to prevent unnecessary strain and wear on the machine.

Regularly calibrating the machine is another important maintenance tip for keeping your copper wire drawing machine in top condition. Calibration ensures that the machine is operating at its optimal performance level and producing high-quality wires. Follow the manufacturer’s guidelines for calibration intervals and procedures to maintain the machine’s accuracy and efficiency.

Lastly, it is important to train your operators on proper machine maintenance and operation. Well-trained operators can identify potential issues early, perform routine maintenance tasks, and operate the machine safely and efficiently. Provide regular training sessions for your operators to ensure they are familiar with the machine’s maintenance requirements and best practices.

In conclusion, regular maintenance is essential for keeping your copper wire drawing machine in top condition. By following these maintenance tips, you can ensure the efficient operation of your machine, prolong its lifespan, and produce high-quality copper wires consistently. Remember to inspect and clean the machine regularly, lubricate moving parts, check and replace worn or damaged parts, monitor tension and alignment, calibrate the machine, and train your operators for optimal performance. With proper maintenance, your copper wire drawing machine will continue to be a valuable asset in your manufacturing operations.

Benefits of Using Copper Wire Drawing Machine

Copper wire drawing machines are essential tools in the manufacturing industry for producing high-quality copper wires. These machines are designed to pull a copper rod through a series of dies to reduce its diameter and increase its length. The process involves applying pressure and lubrication to the copper rod to ensure a smooth and consistent drawing process.

One of the main benefits of using a Slip Wire Drawing Machine is the ability to produce copper wires of various diameters. By adjusting the size of the dies, manufacturers can create wires that meet specific requirements for different applications. This flexibility allows for greater customization and versatility in production, making it easier to meet the needs of customers in various industries.

In addition to producing wires of different diameters, copper wire drawing machines also help improve the quality of the final product. The drawing process helps to refine the structure of the copper wire, making it stronger and more durable. This results in wires that are less likely to break or deform during use, ensuring a longer lifespan and better performance in applications such as electrical wiring and telecommunications.

Another advantage of using a copper wire drawing machine is the ability to increase production efficiency. These machines are designed to operate at high speeds, allowing manufacturers to produce large quantities of copper wire in a relatively short amount of time. This can help reduce production costs and lead times, making it easier to meet customer demand and stay competitive in the market.

Furthermore, copper wire drawing machines are designed to be easy to operate and maintain. With proper training and regular maintenance, operators can ensure that the machine runs smoothly and efficiently, minimizing downtime and maximizing productivity. This can help improve overall production efficiency and reduce the risk of costly repairs or replacements.

In addition to these benefits, copper wire drawing machines also offer environmental advantages. The drawing process generates minimal waste, as the copper rod is simply elongated and not cut or removed during production. This helps reduce material waste and energy consumption, making the manufacturing process more sustainable and environmentally friendly.

Overall, the use of copper wire drawing machines offers numerous benefits for manufacturers in the production of high-quality copper wires. From increased customization and quality to improved efficiency and sustainability, these machines play a crucial role in the manufacturing industry. By investing in a copper wire drawing machine, manufacturers can enhance their production capabilities and meet the growing demand for copper wires in various industries.

How to Choose the Right Copper Wire Drawing Machine for Your Needs

Copper wire drawing machines are essential tools for industries that rely on the production of copper wire for various applications. These machines are used to pull copper wire through a series of dies to reduce its diameter and improve its quality. Choosing the right copper wire drawing machine for your needs is crucial to ensure efficient production and high-quality output.

When selecting a copper wire drawing machine, there are several factors to consider. The first consideration is the size and type of wire you will be working with. Different machines are designed to handle different wire sizes and types, so it is important to choose a machine that is compatible with the wire you will be using.

Another important factor to consider is the speed and efficiency of the machine. Some machines are designed to operate at higher speeds, while others are more suitable for slower production. It is important to choose a machine that can meet your production requirements without sacrificing quality.

The number of dies in the machine is also an important consideration. Machines with more dies are able to achieve greater reductions in wire diameter, resulting in higher quality wire. However, machines with fewer dies may be more suitable for smaller production runs or for working with thicker wire.

The quality of the machine itself is also a crucial factor to consider. Look for a machine that is well-built and durable, as this will ensure reliable performance and longevity. It is also important to consider the reputation of the manufacturer, as reputable manufacturers are more likely to produce high-quality machines.

In addition to these factors, it is also important to consider the cost of the machine. While it may be tempting to choose a cheaper machine, it is important to consider the long-term costs of maintenance and repairs. Investing in a higher-quality machine may ultimately save you money in the long run.

When choosing a copper wire drawing machine, it is important to carefully evaluate your needs and consider all of these factors. By taking the time to research and compare different machines, you can ensure that you choose a machine that is well-suited to your production requirements and will provide you with high-quality output.

In conclusion, choosing the right copper wire drawing machine is essential for ensuring efficient production and high-quality output. By considering factors such as wire size, speed, number of dies, machine quality, and cost, you can make an informed decision that will benefit your business in the long run. Take the time to research and compare different machines to find the best option for your needs.