Table of Contents

Merfits of Using Cable Winding Equipment for Efficient Cable Management

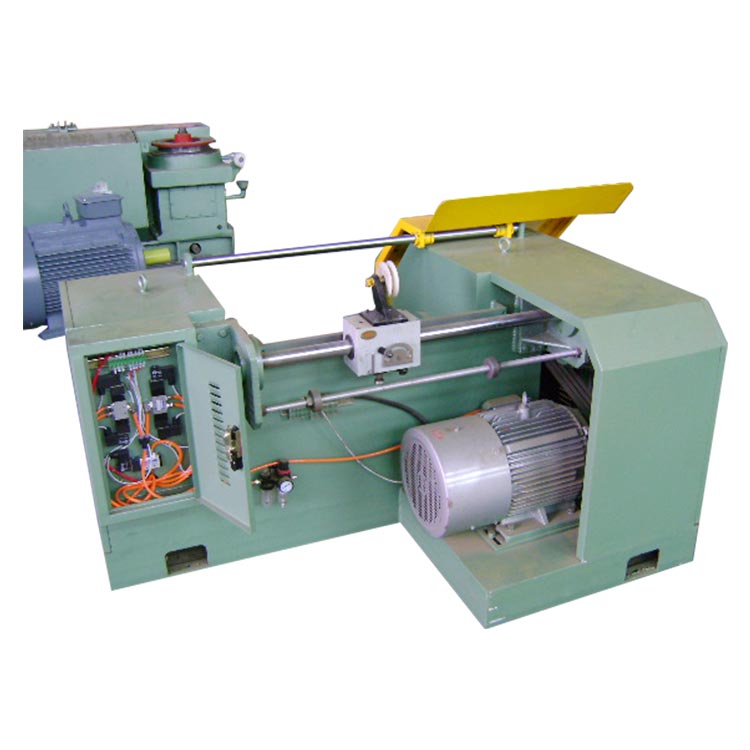

Cable winding and reeling equipment are essential tools for efficient cable management in various industries. These equipment are designed to streamline the process of handling and storing cables, making it easier for workers to access and transport cables as needed. By using cable winding equipment, companies can improve their workflow, reduce the risk of cable damage, and increase overall productivity.

One of the key merits of using cable winding equipment is the ability to organize and store cables in a neat and orderly manner. With cable winding machines, workers can quickly wind up cables and store them in a compact and organized fashion. This not only saves space but also makes it easier to locate and retrieve cables when needed. By keeping cables neatly wound and stored, companies can reduce the risk of tangling, knotting, and damage, which can lead to costly downtime and repairs.

In addition to improving cable organization, cable winding equipment also helps to streamline the process of handling and transporting cables. By using a cable winding machine, workers can quickly wind up cables onto a reel or spool, making it easier to transport and install cables in various locations. This can save time and effort, as workers no longer have to manually wind up cables or struggle with tangled and messy cables. With cable winding equipment, companies can increase efficiency and productivity by simplifying the cable handling process.

Another advantege of using cable winding equipment is the ability to customize the winding process to meet specific requirements. Cable winding machines come in a variety of sizes and configurations, allowing companies to choose the right equipment for their needs. Whether winding small cables for electronics or large cables for industrial applications, there is a cable winding machine that can handle the job. By customizing the winding process, companies can ensure that cables are wound up properly and securely, reducing the risk of damage and ensuring reliable performance.

Furthermore, cable winding equipment can help to extend the lifespan of cables by reducing wear and tear. When cables are wound up and stored properly, they are less likely to be damaged by bending, twisting, or crushing. This can help to prevent cable failures and downtime, saving companies time and money on repairs and replacements. By investing in cable winding equipment, companies can protect their cables and ensure that they remain in good condition for longer periods.

Overall, cable winding equipment offers numerous benefits for efficient cable management in various industries. By organizing and storing cables in a neat and orderly manner, streamlining the cable handling process, customizing the winding process to meet specific requirements, and extending the lifespan of cables, companies can improve their workflow, reduce the risk of cable damage, and increase overall productivity. With the right cable winding equipment, companies can effectively manage their cables and ensure reliable performance in their operations.

How to Choose the Right Reeling Equipment for Your Industrial Needs

Cable winding and reeling equipment play a crucial role in various industries, from manufacturing to construction. These machines are designed to efficiently wind and reel in cables, hoses, and other materials, making them essential for keeping worksites organized and safe. Choosing the right reeling equipment for your industrial needs is important to ensure smooth operations and maximize productivity.

When selecting cable winding and reeling equipment, there are several factors to consider. The first thing to think about is the type of material you will be working with. Different materials have different properties, such as weight, flexibility, and length, which can affect the type of reeling equipment you need. For example, if you are working with heavy-duty cables, you will need a machine that can handle the weight and size of the cables without causing damage.

Another important factor to consider is the size of the worksite and the space available for the reeling equipment. Some machines are compact and portable, making them ideal for smaller worksites with limited space. On the other hand, larger worksites may require more heavy-duty equipment that can handle larger volumes of material.

It is also important to consider the speed and efficiency of the reeling equipment. Some machines are designed to wind and reel in cables quickly, while others may take longer to complete the task. Depending on your specific needs, you may need a machine that can handle high volumes of material in a short amount of time.

Additionally, consider the safety features of the reeling equipment. Safety should always be a top priority in any industrial setting, so it is important to choose equipment that is designed with safety in mind. Look for machines that have built-in safety features, such as automatic shut-off mechanisms and emergency stop buttons, to prevent accidents and injuries.

When choosing cable winding and reeling equipment, it is also important to consider the maintenance and upkeep of the machines. Some machines require regular maintenance to keep them running smoothly, while others may be more low-maintenance. Consider your maintenance capabilities and schedule when selecting equipment to ensure that you can keep it in good working condition.

In conclusion, choosing the right reeling equipment for your industrial needs is essential for maintaining a safe and efficient worksite. Consider factors such as the type of material you will be working with, the size of the worksite, the speed and efficiency of the equipment, safety features, and maintenance requirements when selecting a machine. By carefully considering these factors, you can choose the best reeling equipment for your specific needs and ensure smooth operations in your industrial setting.