Table of Contents

Maintenance Tips for Automatic Wire Straightening and Cutting Machine

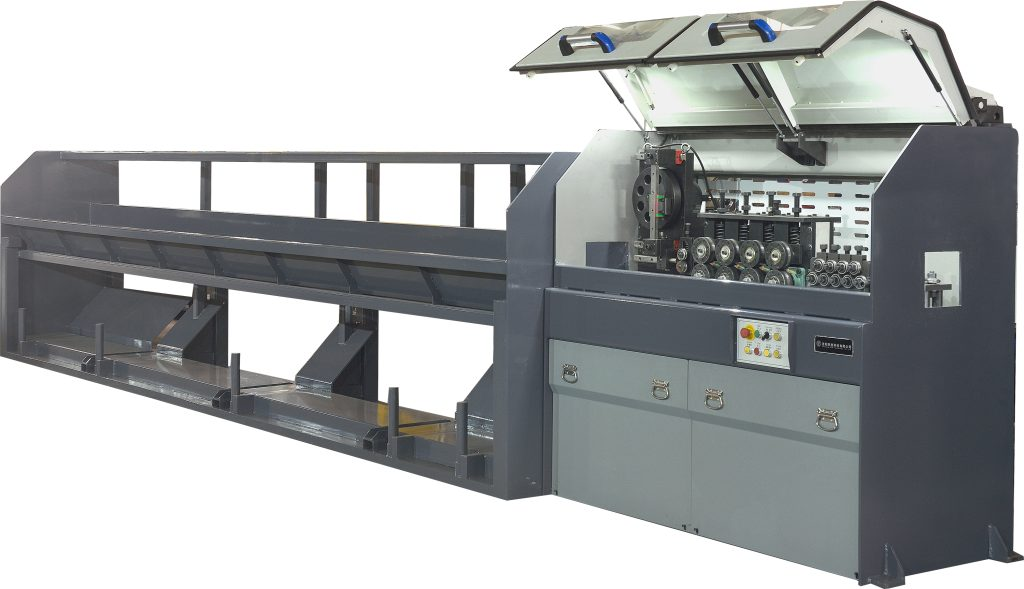

Automatic wire straightening and cutting machine are are designed to straighten and cut wires quickly and accurately, saving time and labor costs. However, like any other piece of equipment, automatic wire straightening and cutting machine require regular maintenance to ensure optimal performance and longevity.

One of the most important maintenance tasks for automatic wire straightening and cutting machine is keeping the machine clean. Dust, dirt, and debris can accumulate on the machine’s components, leading to malfunctions and decreased efficiency. Regularly cleaning the machine with a soft brush or cloth can help prevent these issues and prolong the machine’s lifespan.

In addition to keeping the machine clean, it is also important to regularly lubricate the moving parts of the machine. Lubrication helps reduce friction between components, preventing wear and tear and ensuring smooth operation. Be sure to use the appropriate type of lubricant recommended by the manufacturer and follow the recommended schedule for lubrication.

Another crucial maintenance task for automatic Wire Straightening and Cutting Machines are inspecting and replacing worn or damaged parts. Over time, the machine’s components may wear out or become damaged, affecting its performance. Regularly inspecting the machine for signs of wear and tear, such as frayed wires or loose bolts, can help prevent more serious issues from occurring. Replace any worn or damaged parts promptly to avoid costly repairs or downtime.

It is also important to regularly calibrate the machine to ensure accurate wire straightening and cutting. Calibration ensures that the machine is operating within the specified tolerances, producing wires of consistent length and diameter. Follow the manufacturer’s guidelines for calibration and perform this task regularly to maintain the machine’s accuracy.

Additionally, it is essential to check the machine’s electrical components regularly. Loose connections, damaged wires, or faulty sensors can cause the machine to malfunction or stop working altogether. Inspect the electrical components for signs of damage or wear, and replace any faulty parts as needed. It is also a good idea to have a qualified technician perform regular electrical inspections to ensure the machine’s safety and reliability.

Finally, it is important to store the machine properly when not in use. Keep the machine in a clean, dry, and well-ventilated area to prevent rust and corrosion. Cover the machine with a protective tarp or sheet to shield it from dust and debris. Proper storage can help prolong the machine’s lifespan and reduce the need for repairs.

In conclusion, regular maintenance is essential for automatic wire straightening and cutting machines to ensure optimal performance and longevity. By keeping the machine clean, lubricating moving parts, inspecting and replacing worn or damaged parts, calibrating the machine, checking electrical components, and storing the machine properly, you can prevent costly repairs and downtime. Follow these maintenance tips to keep your automatic wire straightening and cutting machine in top condition and maximize its efficiency.

How to Choose the Right Automatic Wire Straightening and Cutting Machine for Your Needs

Automatic wire straightening and cutting machines are essential tools in various industries that require precise and efficient wire processing. These machines can significantly increase productivity and accuracy in wire cutting and straightening tasks, making them a valuable investment for businesses looking to streamline their operations. However, with a wide range of options available in the market, choosing the right automatic Straightening And Cutting Machine For Steel Bar can be a daunting task. In this article, we will discuss some key factors to consider when selecting the right machine for your specific needs.

One of the first things to consider when choosing an automatic wire straightening and cutting machine is the type of wire you will be processing. Different machines are designed to handle different types and sizes of wire, so it is important to choose a machine that is compatible with the wire you will be working with. Additionally, consider the production volume and speed requirements of your operation. Some machines are designed for high-speed production, while others are more suitable for smaller-scale operations.

Another important factor to consider is the level of automation and customization offered by the machine. Some machines come with advanced features such as programmable settings, touch screen interfaces, and automatic wire feeding systems, which can greatly improve efficiency and accuracy in wire processing tasks. Consider your specific requirements and choose a machine that offers the level of automation and customization that best suits your needs.

It is also important to consider the quality and reliability of the machine. Look for machines from reputable manufacturers with a track record of producing high-quality, durable machines. Consider reading reviews and testimonials from other users to get an idea of the machine’s performance and reliability in real-world applications. Additionally, consider the availability of spare parts and technical support, as these can be crucial in ensuring the long-term reliability and performance of the machine.

When choosing an automatic wire straightening and cutting machine, it is also important to consider the space and layout of your workspace. Some machines are compact and portable, making them ideal for smaller workspaces or mobile operations. Others are larger and more stationary, requiring a dedicated space for installation. Consider the size and layout of your workspace and choose a machine that fits your specific requirements.

Finally, consider your budget and cost considerations when choosing an automatic wire straightening and cutting machine. Prices can vary significantly depending on the features, capabilities, and brand of the machine. Consider your budget and weigh the cost against the features and capabilities offered by the machine. Remember that investing in a high-quality machine can result in long-term cost savings through increased productivity and efficiency.

In conclusion, choosing the right automatic wire straightening and cutting machine requires careful consideration of various factors such as the type of wire, production volume, level of automation, quality and reliability, workspace layout, and budget. By taking the time to evaluate your specific requirements and research different options, you can choose a machine that best suits your needs and helps you streamline your wire processing operations. Remember to consider the long-term benefits and potential cost savings of investing in a high-quality machine, as this can greatly impact the success and efficiency of your business operations.