Benefits of Using an Automatic Straightening & Cutting Machine

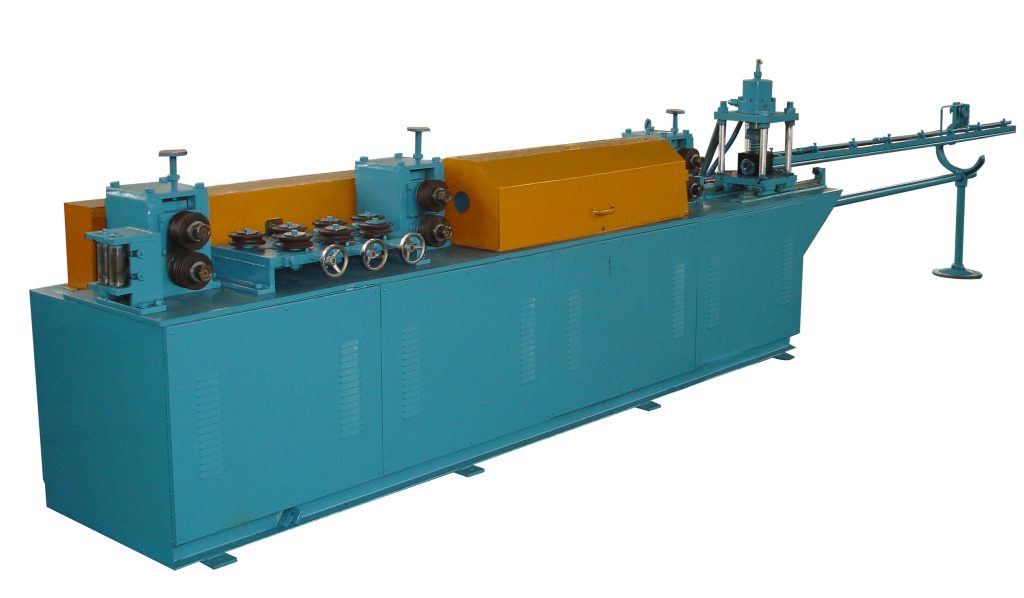

An Automatic Wire Straightening and Cutting Machines are valuable piece of equipment that offers numerous benefits to businesses in various industries. This machine is designed to straighten and cut wire, rod, or tube materials quickly and accurately, making it an essential tool for manufacturers looking to increase efficiency and productivity in their operations.

One of the key benefits of using an automatic straightening and cutting machine is its ability to improve the quality of the finished product. By automating the straightening and cutting process, this machine ensures that each piece of material is cut to the exact length and straightness required, resulting in a consistent and uniform product every time. This level of precision is difficult to achieve manually and can help businesses maintain high standards of quality in their products.

In addition to improving product quality, an automatic straightening and cutting machine can also help businesses save time and labor costs. Manual straightening and cutting processes are time-consuming and labor-intensive, requiring skilled workers to perform these tasks. By automating these processes, businesses can significantly reduce the amount of time and labor required to produce their products, allowing them to increase production capacity and meet customer demand more efficiently.

Furthermore, an automatic straightening and cutting machine can also help businesses reduce material waste. Manual cutting processes often result in uneven cuts and material waste, as workers may struggle to cut materials accurately and consistently. By using an automatic machine, businesses can minimize material waste and maximize the use of their raw materials, ultimately saving money and reducing their environmental impact.

Another benefit of using an automatic Straightening And Cutting Machine For Steel Bar is its versatility. These machines are capable of straightening and cutting a wide range of materials, including wire, rod, and tube materials of various sizes and shapes. This versatility makes them suitable for use in a variety of industries, from construction and manufacturing to automotive and aerospace.

Additionally, an automatic straightening and cutting machine can help businesses improve workplace safety. Manual cutting processes can be dangerous, as workers are often required to handle sharp tools and heavy materials. By automating these processes, businesses can reduce the risk of workplace accidents and injuries, creating a safer working environment for their employees.

Overall, an automatic straightening and cutting machine offers numerous benefits to businesses looking to improve efficiency, productivity, and product quality in their operations. By automating the straightening and cutting process, businesses can save time and labor costs, reduce material waste, increase production capacity, and improve workplace safety. With its versatility and precision, this machine is a valuable investment for any business looking to streamline their manufacturing processes and stay competitive in today’s market.