Table of Contents

Maintenance Tips for Automatic Straightening and Cutting Machines

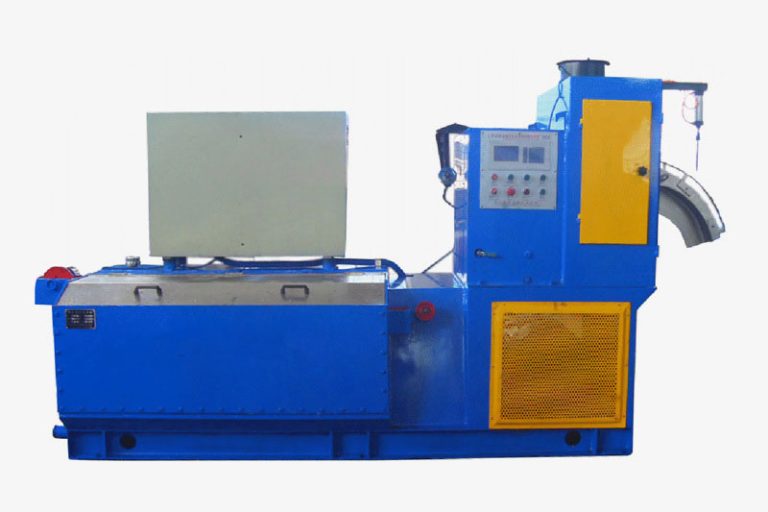

Automatic Wire Straightening and Cutting Machine are essential tools in various industries, such as construction, manufacturing, and automotive. These machines are designed to efficiently straighten and cut metal rods, wires, and tubes to precise lengths and dimensions. To ensure the optimal performance and longevity of these machines, regular maintenance is crucial. In this article, we will discuss some maintenance tips for automatic straightening and cutting machines.

One of the most important maintenance tasks for automatic straightening and cutting machines is keeping them clean. Dust, debris, and metal shavings can accumulate on the machine’s components, leading to decreased performance and potential damage. Regularly cleaning the machine with a soft brush or compressed air can help prevent these issues. Additionally, lubricating moving parts with the appropriate lubricant can help reduce friction and wear, extending the machine’s lifespan.

Another key maintenance tip is to regularly inspect the machine for any signs of wear or damage. Check the cutting blades, rollers, and guides for any signs of wear or misalignment. Replace any worn or damaged parts immediately to prevent further damage to the machine and ensure accurate cutting and straightening.

Calibrating the machine regularly is also essential for maintaining its accuracy and precision. Over time, the machine’s settings may drift, leading to inaccuracies in cutting lengths and dimensions. By calibrating the machine according to the manufacturer’s specifications, you can ensure that it continues to produce high-quality results.

In addition to regular maintenance tasks, it is important to follow the manufacturer’s recommended maintenance schedule. This may include replacing certain parts at specific intervals, such as cutting blades or bearings. By following the manufacturer’s guidelines, you can prevent unexpected breakdowns and costly repairs.

Proper storage of the machine when not in use is also important for maintaining its condition. Store the machine in a clean, dry environment away from moisture and extreme temperatures. Covering the machine with a protective tarp or sheet can help prevent dust and debris from accumulating on its components.

Regularly inspecting and maintaining the electrical components of the machine is crucial for ensuring its safe operation. Check the power cords, switches, and connections for any signs of damage or wear. Replace any damaged components immediately to prevent electrical hazards.

Lastly, training your operators on proper machine maintenance and operation is essential for maximizing the machine’s lifespan and performance. Ensure that your operators are familiar with the machine’s maintenance requirements and procedures. Encourage them to report any issues or abnormalities they notice during operation.

In conclusion, regular maintenance is essential for ensuring the optimal performance and longevity of automatic straightening and cutting machines. By following these maintenance tips, you can prevent unexpected breakdowns, extend the machine’s lifespan, and ensure accurate cutting and straightening. Remember to clean the machine regularly, inspect for wear and damage, calibrate as needed, follow the manufacturer’s maintenance schedule, store the machine properly, inspect electrical components, and train your operators on proper maintenance procedures. By taking care of your automatic straightening and cutting machine, you can maximize its efficiency and productivity.

Benefits of Using Automatic Straightening and Cutting Machines

Automatic Straightening And Cutting Machine For Welding Electrodes have revolutionized the manufacturing industry by streamlining the process of producing straightened and accurately cut materials. These machines offer a wide range of benefits that can significantly improve efficiency, accuracy, and overall productivity in various industries.

One of the key benefits of using automatic straightening and cutting machines is the increased speed at which materials can be processed. These machines are capable of straightening and cutting materials at a much faster rate than manual methods, allowing for higher production output in a shorter amount of time. This increased speed can help companies meet tight deadlines and fulfill large orders more efficiently.

In addition to speed, automatic straightening and cutting machines also offer improved accuracy in the cutting process. These machines are equipped with advanced technology that ensures precise measurements and cuts, resulting in materials that are consistently straight and uniform in size. This level of accuracy is crucial in industries where precision is essential, such as construction, automotive, and aerospace.

Furthermore, automatic Straightening And Cutting Machine For Steel Bar can help reduce material waste by minimizing errors and inconsistencies in the cutting process. With manual methods, there is a higher risk of human error, which can lead to wasted materials and increased costs. By using automatic machines, companies can minimize these risks and optimize their material usage, ultimately saving time and money in the long run.

Another benefit of using automatic straightening and cutting machines is the improved safety they provide for workers. Manual cutting methods can be dangerous and labor-intensive, putting workers at risk of injury. Automatic machines eliminate the need for manual labor in the cutting process, reducing the risk of accidents and creating a safer work environment for employees.

Additionally, automatic straightening and cutting machines are versatile and can be used to process a wide range of materials, including steel, aluminum, copper, and more. This versatility makes these machines suitable for a variety of industries and applications, from manufacturing to construction to automotive. Companies can use these machines to cut materials of different sizes and shapes, making them a valuable asset in any production facility.

Overall, the benefits of using automatic straightening and cutting machines are clear. These machines offer increased speed, accuracy, efficiency, and safety in the manufacturing process, ultimately leading to higher productivity and cost savings for companies. By investing in automatic machines, companies can improve their operations and stay competitive in today’s fast-paced market.

In conclusion, automatic straightening and cutting machines are a valuable tool for companies looking to streamline their production processes and improve overall efficiency. With their speed, accuracy, versatility, and safety features, these machines offer a wide range of benefits that can help companies meet their production goals and stay ahead of the competition. Whether you are in the construction, automotive, or manufacturing industry, investing in automatic straightening and cutting machines can be a wise decision that pays off in the long run.

How to Choose the Right Automatic Straightening and Cutting Machine for Your Business

Automatic Wire Straightening and Cutting Machines are essential tools for businesses in various industries, such as construction, manufacturing, and automotive. These machines are designed to streamline the process of straightening and cutting metal rods, wires, and tubes with precision and efficiency. With the advancement of technology, automatic straightening and cutting machines have become more sophisticated, offering a wide range of features and capabilities to meet the diverse needs of businesses.

When choosing the right automatic straightening and cutting machine for your business, there are several factors to consider. One of the most important factors is the type of material you will be working with. Different machines are designed to handle different types of materials, such as steel, aluminum, copper, and more. It is essential to choose a machine that is compatible with the materials you will be using to ensure optimal performance and quality results.

Another crucial factor to consider is the size and capacity of the machine. Automatic straightening and cutting machines come in various sizes and capacities, ranging from small, compact machines for light-duty applications to large, heavy-duty machines for high-volume production. It is essential to choose a machine that can handle the volume of work you require while also fitting within the space constraints of your facility.

Additionally, consider the level of automation and control offered by the machine. Some machines are fully automatic, with programmable settings and advanced features that allow for precise and consistent results. Others may offer manual control options for more flexibility and customization. Depending on your specific needs and preferences, choose a machine that offers the level of automation and control that best suits your business requirements.

Furthermore, consider the speed and accuracy of the machine. Automatic straightening and cutting machines are designed to increase productivity and efficiency by cutting down on processing time and minimizing errors. Look for a machine that offers fast cutting speeds and high accuracy to ensure quick turnaround times and high-quality results.

In addition to these factors, it is essential to consider the overall quality and reliability of the machine. Choose a machine from a reputable manufacturer with a track record of producing high-quality, durable machines that are built to last. Look for machines that are made from high-quality materials and components to ensure long-term performance and reliability.

Finally, consider the after-sales support and service offered by the manufacturer. Choose a manufacturer that provides comprehensive support, including installation, training, maintenance, and repair services to ensure that your machine operates smoothly and efficiently throughout its lifespan.

In conclusion, choosing the right automatic straightening and cutting machine for your business is a crucial decision that can impact the productivity and efficiency of your operations. Consider factors such as material compatibility, size and capacity, automation and control, speed and accuracy, quality and reliability, and after-sales support when selecting a machine. By carefully evaluating these factors and choosing a machine that meets your specific needs and requirements, you can ensure that your business benefits from the advantages of automatic straightening and cutting technology.