Table of Contents

Maintenance Tips for Aluminium Wire Drawing Machine

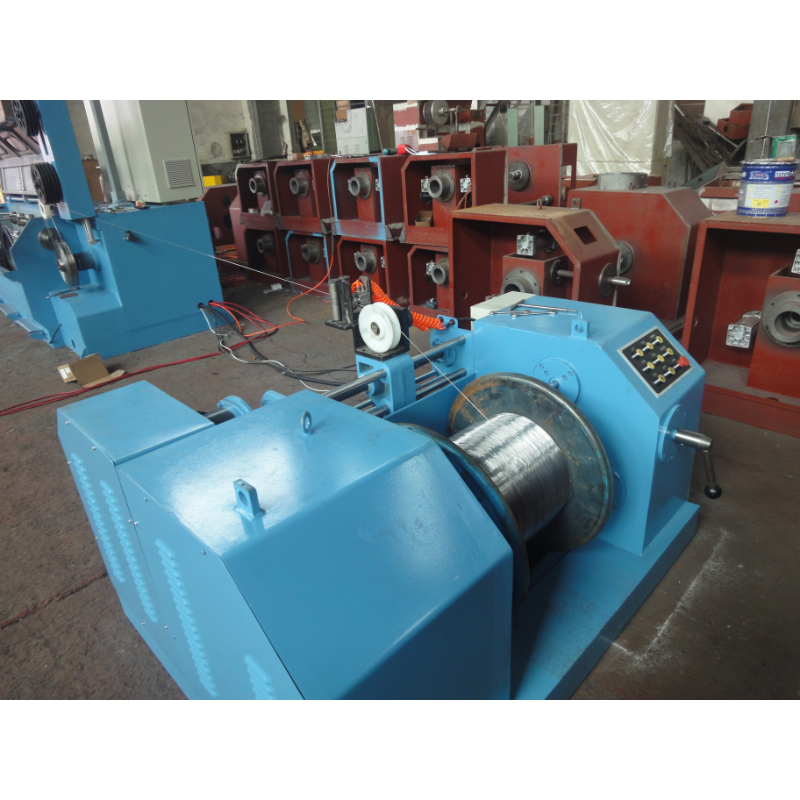

Aluminium wire drawing machines are essential equipment in the manufacturing industry, used to produce high-quality aluminium wires of various diameters. To ensure the smooth operation and longevity of these machines, regular maintenance is crucial. In this article, we will discuss some important maintenance tips for aluminium wire drawing machines.

First and foremost, it is important to regularly inspect the machine for any signs of wear and tear. Check for loose or damaged parts, such as belts, pulleys, and bearings. Replace any worn-out components immediately to prevent further damage to the machine and ensure optimal performance.

Another important maintenance tip is to lubricate the moving parts of the machine regularly. Proper lubrication helps reduce friction and wear, prolonging the lifespan of the machine. Use the recommended lubricants for each part of the machine and follow the manufacturer’s guidelines for lubrication intervals.

In addition to regular inspections and lubrication, it is important to keep the machine clean. Dust, dirt, and debris can accumulate on the machine over time, affecting its performance. Clean the machine regularly using a soft brush or cloth to remove any buildup. Pay special attention to the wire drawing dies and other critical components to prevent contamination and ensure smooth operation.

Furthermore, it is important to monitor the tension and speed of the wire drawing process. Improper tension or speed can lead to wire breakage or other issues. Make sure to adjust the tension and speed settings according to the wire diameter and material being drawn. Regularly check the wire tension and speed indicators to ensure they are within the recommended range.

Regularly calibrating the machine is also essential for maintaining its accuracy and efficiency. Use calibrated measuring tools to check the wire diameter and adjust the machine settings as needed. Proper calibration ensures that the machine produces wires of consistent diameter and quality.

Lastly, it is important to train operators on proper machine maintenance and operation. Provide training on how to perform routine maintenance tasks, such as lubrication, cleaning, and inspection. Educate operators on the importance of following maintenance schedules and guidelines to prevent costly downtime and repairs.

In conclusion, regular maintenance is key to ensuring the optimal performance and longevity of Wet Wire Drawing Machine. By following these maintenance tips, you can keep your machine in top condition and maximize its productivity. Remember to inspect the machine regularly, lubricate moving parts, keep it clean, monitor tension and speed, calibrate the machine, and train operators on proper maintenance practices. With proper care and maintenance, your aluminium wire drawing machine will continue to produce high-quality wires for years to come.

Benefits of Using Aluminium Wire Drawing Machine

Aluminium wire drawing machines are essential tools in the manufacturing industry for producing high-quality aluminium wires. These machines are designed to pull aluminium rods through a series of dies to reduce their diameter and improve their mechanical properties. The process involves applying pressure and lubrication to the rods to ensure a smooth and consistent drawing operation.

One of the key benefits of using an aluminium wire drawing machine is the ability to produce wires with precise dimensions. These machines are equipped with multiple dies that can be adjusted to achieve the desired wire diameter. This level of precision is crucial for industries that require uniform wire sizes for their products, such as electrical wiring, automotive components, and construction materials.

In addition to producing wires with precise dimensions, aluminium wire drawing machines also offer improved surface finish. The drawing process helps to remove surface imperfections and contaminants from the aluminium rods, resulting in smooth and clean wires. This is important for applications where surface quality is critical, such as in the production of fine wires for electronics or medical devices.

Another advantage of using an aluminium wire drawing machine is the ability to control the mechanical properties of the wires. By adjusting the drawing speed, temperature, and lubrication, manufacturers can tailor the strength, ductility, and conductivity of the wires to meet specific requirements. This flexibility allows for the production of customised wires for a wide range of applications.

Furthermore, aluminium wire drawing machines are highly efficient and cost-effective. These machines are designed to operate at high speeds, allowing for rapid production of large quantities of wires. This efficiency helps to reduce manufacturing lead times and increase productivity. Additionally, the use of aluminium rods as raw materials is more economical compared to other metals, making aluminium wire drawing a cost-effective solution for wire production.

Moreover, aluminium wire drawing machines are versatile and can accommodate a wide range of wire sizes and materials. Whether manufacturers need to produce thin wires for electronics or thick wires for industrial applications, these machines can be adjusted to meet various production requirements. This versatility makes aluminium wire drawing machines a valuable asset for manufacturers in diverse industries.

In conclusion, the benefits of using an aluminium wire drawing machine are numerous and significant. From producing wires with precise dimensions and improved surface finish to controlling mechanical properties and increasing efficiency, these machines offer a range of advantages for manufacturers. With their versatility and cost-effectiveness, aluminium wire drawing machines are essential tools for producing high-quality aluminium wires for various applications. Whether in the electrical, automotive, or construction industry, these machines play a crucial role in meeting the demand for reliable and efficient wire production.

How to Choose the Right Aluminium Wire Drawing Machine for Your Business

Aluminium wire drawing machines are essential equipment for businesses involved in the production of aluminium wires. These machines are used to reduce the diameter of aluminium rods or wires by pulling them through a series of dies, resulting in a smoother and more uniform wire. Choosing the right aluminium wire drawing machine for your business is crucial to ensure efficient production and high-quality output.

When selecting an aluminium wire drawing machine, there are several factors to consider. The first consideration is the size and type of aluminium wire you will be producing. Different machines are designed to handle different wire sizes and types, so it is important to choose a machine that is suitable for your specific requirements. Additionally, consider the production capacity of the machine. If you have a high volume of production, you will need a machine that can handle the workload efficiently.

Another important factor to consider is the number of dies on the machine. The number of dies determines the number of times the wire will be drawn through the machine, which affects the final diameter of the wire. Machines with more dies are capable of producing finer wires, while machines with fewer dies are better suited for thicker wires. Consider your desired wire diameter and choose a machine with the appropriate number of dies to achieve the desired results.

It is also important to consider the speed of the machine. The speed at which the wire is drawn through the machine affects the production efficiency and output quality. Higher speeds can result in faster production but may also lead to increased wear and tear on the machine. Consider your production requirements and choose a machine with a speed that meets your needs without compromising on quality.

Additionally, consider the power and drive system of the machine. The power of the machine determines its ability to handle the workload, while the drive system affects the efficiency and reliability of the machine. Choose a machine with a powerful motor and a reliable drive system to ensure smooth operation and consistent output.

When choosing an aluminium wire drawing machine, it is also important to consider the reputation and reliability of the manufacturer. Look for a reputable manufacturer with a track record of producing high-quality machines. Read reviews and testimonials from other customers to gauge the reliability and performance of the machine.

In conclusion, choosing the right aluminium wire drawing machine for your business is essential to ensure efficient production and high-quality output. Consider factors such as wire size, production capacity, number of dies, speed, power, drive system, and manufacturer reputation when making your decision. By carefully evaluating these factors, you can select a machine that meets your specific requirements and helps you achieve success in your aluminium wire production business.