Table of Contents

How to Properly Maintain and Extend the Lifespan of a Wire Descaling Belt Grinding Machine

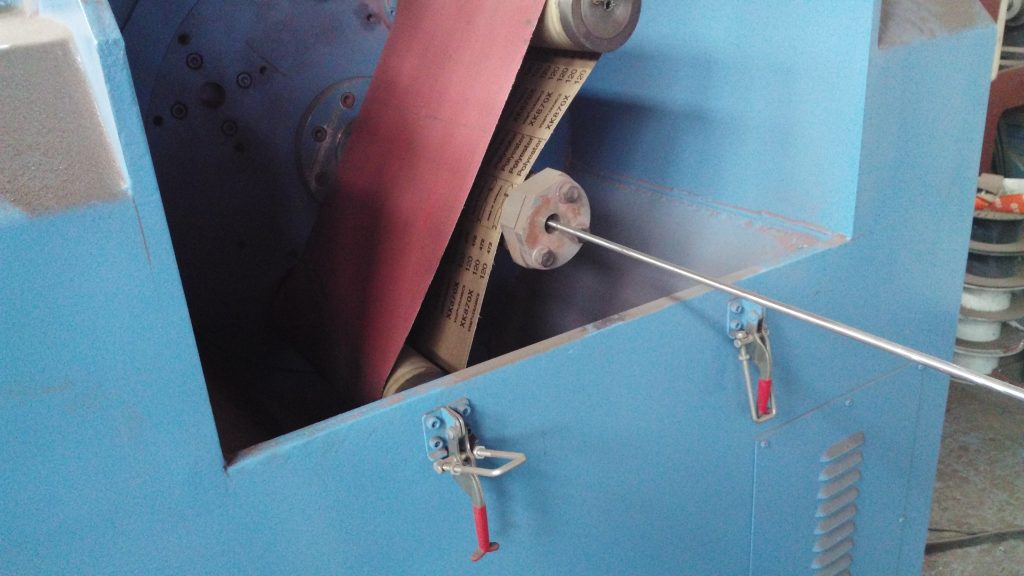

Wire descaling belt grinding machines are essential tools in the metalworking industry, used for removing scale, rust, and other surface imperfections from metal wires. To ensure the machine operates efficiently and effectively, proper maintenance is crucial. By following a few simple steps, you can extend the lifespan of your wire descaling belt grinding machine and keep it in optimal working condition.

One of the most important maintenance tasks for a wire descaling belt grinding machine is regular cleaning. After each use, it is essential to clean the machine thoroughly to remove any debris, dust, or metal particles that may have accumulated on the belts or in the machine’s components. This will prevent build-up and ensure that the machine operates smoothly.

In addition to regular cleaning, it is also important to inspect the machine for any signs of wear or damage. Check the belts, rollers, and other components for any signs of wear, such as fraying or cracking. If any parts are damaged, they should be replaced immediately to prevent further damage to the machine.

Another important maintenance task for a wire Sand Belt Grinding Descaler is lubrication. Proper lubrication of the machine’s moving parts will help reduce friction and wear, extending the lifespan of the machine. Be sure to use the correct type of lubricant recommended by the manufacturer and follow the recommended schedule for lubrication.

In addition to regular cleaning, inspection, and lubrication, it is also important to calibrate the machine regularly. Calibration ensures that the machine is operating at the correct settings and will help maintain the quality of the finished product. Follow the manufacturer’s guidelines for calibration and make any necessary adjustments as needed.

Proper storage of the wire descaling belt grinding machine is also important for maintaining its lifespan. Store the machine in a clean, dry environment away from moisture and extreme temperatures. Cover the machine when not in use to protect it from dust and debris.

Regular maintenance and proper care of your wire descaling belt grinding machine will not only extend its lifespan but also ensure that it operates efficiently and effectively. By following these simple maintenance tips, you can keep your machine in optimal working condition and avoid costly repairs or replacements.

In conclusion, proper maintenance is essential for extending the lifespan of a wire descaling belt grinding machine. Regular cleaning, inspection, lubrication, calibration, and storage are all important tasks that should be performed to keep the machine in optimal working condition. By following these maintenance tips, you can ensure that your machine operates efficiently and effectively for years to come.

Benefits of Using Wire Descaling Belt Grinding Machine in Metal Fabrication

Metal fabrication is a complex process that involves shaping and manipulating metal materials to create various products. One crucial step in metal fabrication is descaling, which involves removing oxides, rust, and other impurities from the surface of the metal. This is essential to ensure that the metal is clean and free from contaminants before further processing. One effective method of descaling metal is through the use of a wire descaling belt grinding machine.

Wire Sanding Belt Grinding Descaler are specialized tools designed to efficiently remove scale and other impurities from metal surfaces. These machines use abrasive belts made of wire to grind away the surface contaminants, leaving behind a clean and smooth metal surface. There are several benefits to using a wire descaling belt grinding machine in metal fabrication.

One of the primary benefits of using a wire descaling belt grinding machine is its efficiency. These machines are designed to quickly and effectively remove scale and other impurities from metal surfaces, saving time and labor in the descaling process. This can help metal fabricators increase their productivity and meet tight production deadlines.

In addition to being efficient, wire descaling belt grinding machines are also highly versatile. These machines can be used on a wide range of metal materials, including steel, aluminum, and stainless steel. This versatility makes them a valuable tool for metal fabricators working with different types of metals.

Another benefit of using a wire descaling belt grinding machine is the quality of the descaled surface it produces. These machines are capable of achieving a high level of precision and consistency in descaling, resulting in a clean and uniform surface finish. This is important for ensuring the quality and integrity of the metal products being fabricated.

Furthermore, wire descaling belt grinding machines are easy to operate and maintain. These machines are designed with user-friendly controls and features that make them simple to use, even for operators with minimal experience. Additionally, maintenance requirements for these machines are minimal, reducing downtime and ensuring continuous operation.

Using a wire descaling belt grinding machine in metal fabrication can also help improve workplace safety. These machines are equipped with safety features such as guards and emergency stop buttons to protect operators from accidents and injuries. By providing a safe working environment, wire descaling belt grinding machines can help metal fabricators comply with safety regulations and prevent workplace incidents.

Overall, the benefits of using a wire descaling belt grinding machine in metal fabrication are numerous. From increased efficiency and versatility to improved surface quality and workplace safety, these machines offer a range of advantages that can help metal fabricators streamline their descaling process and enhance the quality of their products. By investing in a wire descaling belt grinding machine, metal fabricators can improve their productivity, quality, and safety, ultimately leading to greater success in the competitive metal fabrication industry.