Understanding the Benefits of Using Flat Wire Precision Layer Winding Machine

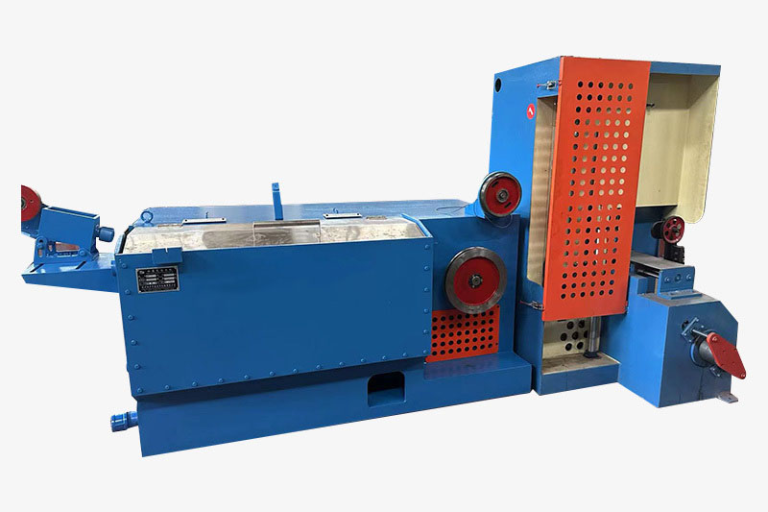

Flat Wire Or Cable Precision Layer Winding Machine are a crucial piece of equipment in the manufacturing industry, particularly for industries that require precise and efficient winding of flat wires. These machines offer a wide range of benefits that can significantly improve the quality and efficiency of the winding process.

One of the key benefits of using a flat wire precision layer winding machine is the ability to achieve consistent and uniform winding. These machines are designed to wind flat wires with precision, ensuring that each layer is wound evenly and tightly. This level of consistency is essential for ensuring the quality and performance of the final product, as any inconsistencies in the winding process can lead to issues such as uneven tension or gaps in the winding.

In addition to ensuring uniform winding, Welding Wire Precision Layer Winding Machine also offer increased efficiency in the winding process. These machines are equipped with advanced technology that allows for high-speed winding, reducing the time and labor required to wind flat wires manually. This not only helps to increase productivity but also reduces the risk of human error, resulting in higher quality and more reliable products.

Furthermore, flat wire precision layer winding machines are highly versatile and can be customized to meet the specific needs of different industries. Whether you are winding flat wires for electrical components, transformers, or any other application, these machines can be tailored to accommodate various wire sizes, materials, and winding patterns. This flexibility allows manufacturers to produce a wide range of products with precision and efficiency.

Another significant benefit of using a flat wire precision layer winding machine is the reduction in material waste. These machines are designed to minimize the amount of wire wasted during the winding process, ensuring that manufacturers can maximize their material usage and reduce costs. This is particularly important for industries that work with expensive or hard-to-source materials, as minimizing waste can lead to significant cost savings in the long run.

Additionally, flat wire precision layer winding machines are designed to be user-friendly and easy to operate. Manufacturers can easily program the machine to meet their specific winding requirements, and the automated features of these machines help to streamline the winding process. This not only reduces the need for manual labor but also allows operators to focus on other tasks, increasing overall efficiency in the manufacturing process.

Overall, the benefits of using a flat wire precision layer winding machine are clear. From achieving consistent and uniform winding to increasing efficiency and reducing material waste, these machines offer a wide range of advantages for manufacturers in various industries. By investing in a flat wire precision layer winding machine, manufacturers can improve the quality of their products, increase productivity, and reduce costs, ultimately leading to a more competitive and successful manufacturing operation.