Table of Contents

How to Choose the Right High Speed Cutting Machine for Welding Electrodes

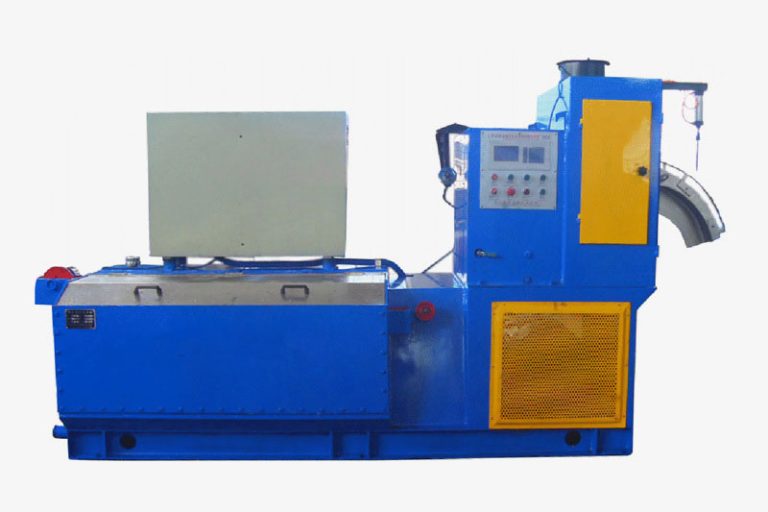

High speed cutting machines are essential tools in the manufacturing process of welding electrodes. These machines are designed to cut electrodes to precise lengths quickly and efficiently, ensuring that the electrodes meet the required specifications for welding applications. Choosing the right high speed Straightening And Cutting Machine For Welding Electrodes are crucial to the quality and efficiency of the manufacturing process.

When selecting a high speed cutting machine for welding electrodes, there are several factors to consider. The first factor to consider is the type of electrodes that will be cut. Different types of electrodes require different cutting techniques and machinery. For example, solid electrodes may require a different cutting machine than flux-cored electrodes. It is important to choose a cutting machine that is specifically designed for the type of electrodes being manufactured.

Another important factor to consider when choosing a high speed cutting machine for welding electrodes is the cutting speed and accuracy of the machine. High speed cutting machines are designed to cut electrodes quickly and accurately, reducing production time and increasing efficiency. It is important to choose a cutting machine that can cut electrodes to the required length with precision and consistency.

The size and capacity of the Wire Straightening and Cutting Machines are also important factors to consider. The size of the cutting machine should be able to accommodate the length and diameter of the electrodes being manufactured. Additionally, the capacity of the cutting machine should be able to handle the volume of electrodes being produced. It is important to choose a cutting machine that can meet the production requirements of the manufacturing process.

The durability and reliability of the cutting machine are also important considerations. High speed cutting machines are often used in high-volume production environments, so it is important to choose a machine that is built to withstand the rigors of continuous use. A durable and reliable cutting machine will help to minimize downtime and maintenance costs, ensuring that the manufacturing process runs smoothly and efficiently.

In addition to these factors, it is also important to consider the cost of the cutting machine. High speed cutting machines can be a significant investment, so it is important to choose a machine that offers good value for money. It is important to consider not only the initial cost of the machine but also the long-term costs of maintenance and operation.

In conclusion, choosing the right high speed cutting machine for welding electrodes is essential to the quality and efficiency of the manufacturing process. By considering factors such as the type of electrodes, cutting speed and accuracy, size and capacity, durability and reliability, and cost, manufacturers can select a cutting machine that meets their production requirements and budget. Investing in a high-quality cutting machine will help to ensure that welding electrodes are cut to precise lengths quickly and efficiently, leading to high-quality welding results.

Maintenance Tips for High Speed Cutting Machine for Welding Electrodes

High speed cutting machines are essential tools in the manufacturing process of welding electrodes. These machines are designed to cut electrodes to precise lengths quickly and efficiently, ensuring that the electrodes meet the required specifications for welding applications. However, like any piece of equipment, automatic wire starightening and cutting machine require regular maintenance to ensure optimal performance and longevity.

One of the most important maintenance tasks for a high speed cutting machine is keeping the cutting blades sharp. Dull blades can result in uneven cuts, which can affect the quality of the electrodes and lead to welding defects. It is recommended to check the sharpness of the blades regularly and sharpen or replace them as needed. This will not only improve the quality of the cuts but also extend the life of the blades.

In addition to keeping the blades sharp, it is important to regularly clean and lubricate the cutting machine. Dust, debris, and metal shavings can accumulate on the machine over time, which can affect its performance. Cleaning the machine regularly with a soft brush or cloth can help prevent build-up and ensure smooth operation. Lubricating moving parts, such as the blade mechanism, can also help reduce friction and wear, prolonging the life of the machine.

Another important maintenance task for a high speed cutting machine is checking and adjusting the blade alignment. Misaligned blades can result in uneven cuts and put unnecessary strain on the machine. It is recommended to check the alignment of the blades regularly and make any necessary adjustments to ensure that they are cutting straight and true. This will help maintain the quality of the cuts and prevent premature wear on the blades.

Regularly inspecting the machine for any signs of wear or damage is also crucial for maintaining its performance. Look for any loose or damaged parts, such as belts, pulleys, or bearings, and replace them as needed. Pay attention to any unusual noises or vibrations coming from the machine, as these can be indicators of underlying issues that need to be addressed. By catching and addressing problems early, you can prevent more serious damage and costly repairs down the line.

Lastly, it is important to follow the manufacturer’s guidelines for maintenance and operation of the high speed cutting machine. This includes proper storage, handling, and usage of the machine to prevent damage and ensure safety. Regularly inspecting and maintaining the machine according to the manufacturer’s recommendations will help prolong its lifespan and ensure consistent performance.

In conclusion, regular maintenance is essential for keeping a high speed cutting machine for welding electrodes in top condition. By keeping the blades sharp, cleaning and lubricating the machine, checking and adjusting blade alignment, inspecting for wear or damage, and following manufacturer guidelines, you can ensure that your cutting machine operates efficiently and produces high-quality electrodes for welding applications. Investing time and effort in maintenance now will pay off in the long run with improved performance and longevity of your equipment.