Table of Contents

Maintenance Tips for Ensuring Longevity and Efficiency of Precision Layer Winding Machines

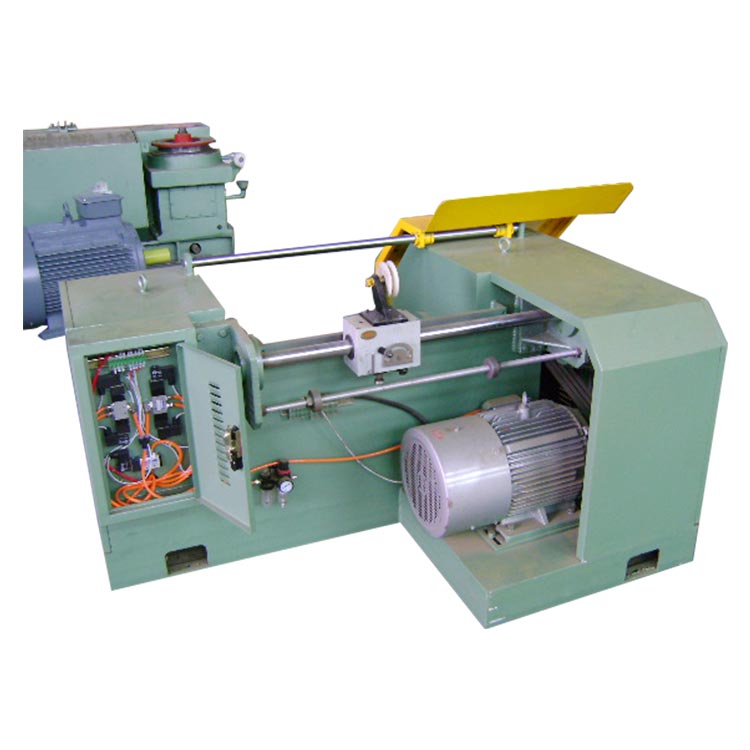

Welding Wire Precision Layer Winding Machine are essential tools in various industries, including the manufacturing of electrical coils, transformers, and inductors. These machines are designed to wind wire or other materials onto a spool or bobbin in a precise and controlled manner, ensuring uniformity and consistency in the final product. To maintain the longevity and efficiency of precision layer winding machines, it is crucial to follow a regular maintenance schedule and implement proper care practices.

One of the most important maintenance tasks for precision layer winding machines is keeping them clean and free of debris. Dust, dirt, and other contaminants can build up on the machine’s components over time, leading to increased friction, wear, and potential damage. Regularly cleaning the machine with a soft brush or cloth and using compressed air to remove any trapped particles can help prevent these issues and ensure smooth operation.

In addition to keeping the machine clean, it is essential to regularly inspect and lubricate its moving parts. Bearings, gears, and other components that experience friction during operation should be checked for signs of wear or damage and lubricated as needed. Using the correct type and amount of lubricant is crucial to prevent premature wear and ensure optimal performance.

Another important aspect of maintaining Flat Wire Or Cable Precision Layer Winding Machine is calibrating them regularly. Calibration ensures that the machine’s settings are accurate and consistent, resulting in precise winding and uniformity in the final product. It is recommended to calibrate the machine at least once a year or more frequently if it is used heavily or experiences significant changes in operating conditions.

In addition to regular maintenance tasks, it is essential to address any issues or malfunctions promptly to prevent further damage and downtime. If the machine is making unusual noises, producing inconsistent winding patterns, or showing other signs of malfunction, it is crucial to investigate the issue and take appropriate action. Consulting the machine’s manual or contacting the manufacturer for assistance can help identify the problem and determine the best course of action.

Proper training and supervision of operators are also essential for maintaining the longevity and efficiency of precision layer winding machines. Operators should be trained on how to operate the machine correctly, follow maintenance procedures, and troubleshoot common issues. Supervisors should monitor the machine’s performance regularly and address any concerns or deviations from standard operating procedures promptly.

In conclusion, maintaining the longevity and efficiency of precision layer winding machines requires a combination of regular maintenance tasks, proper care practices, and prompt attention to any issues or malfunctions. By keeping the machine clean, inspecting and lubricating its moving parts, calibrating it regularly, addressing issues promptly, and providing proper training and supervision to operators, you can ensure that your precision layer winding machine operates smoothly and produces high-quality products consistently. Investing time and effort in maintaining your machine will pay off in the long run by extending its lifespan and maximizing its performance.

Benefits of Using Precision Layer Winding Machines in Manufacturing Processes

Welding Wire Precision Layer Semi-Automatic Winding Machine are a crucial component in many manufacturing processes, providing a level of accuracy and efficiency that is unmatched by manual winding methods. These machines are designed to wind materials such as wire, cable, tubing, or tape onto spools or reels with precision and consistency. By automating the winding process, manufacturers can increase productivity, reduce waste, and improve the overall quality of their products.

One of the key benefits of using precision layer winding machines is the level of accuracy they provide. These machines are equipped with advanced technology that allows them to wind materials with a high degree of precision, ensuring that each layer is wound evenly and tightly. This level of accuracy is essential in industries where consistency is critical, such as the electronics or medical device manufacturing sectors.

In addition to accuracy, precision layer winding machines also offer increased efficiency. These machines are capable of winding materials at a much faster rate than manual methods, allowing manufacturers to produce more products in less time. This increased efficiency can lead to cost savings and improved profitability for companies that rely on precision winding in their manufacturing processes.

Another benefit of using precision layer winding machines is the reduction of waste. By automating the winding process, manufacturers can minimize the amount of material that is wasted during production. This not only helps to reduce costs but also has a positive impact on the environment by reducing the amount of material that ends up in landfills.

Furthermore, welding wire precision layer winding machine can improve the overall quality of products. By ensuring that materials are wound evenly and tightly, these machines help to prevent issues such as tangling, kinking, or stretching that can occur with manual winding methods. This results in products that are more reliable and consistent, leading to higher customer satisfaction and fewer returns or warranty claims.

In addition to these benefits, precision layer winding machines also offer versatility in terms of the types of materials that can be wound. These machines can handle a wide range of materials, from thin wires to thick cables, and can be customized to meet the specific needs of different industries. This flexibility makes precision layer winding machines a valuable asset for manufacturers in a variety of sectors.

Overall, the benefits of using precision layer winding machines in manufacturing processes are clear. From increased accuracy and efficiency to reduced waste and improved product quality, these machines offer a range of advantages that can help companies stay competitive in today’s fast-paced market. By investing in precision winding technology, manufacturers can streamline their production processes, improve their bottom line, and deliver high-quality products to their customers.

How to Choose the Right Precision Layer Winding Machine for Your Business

Precision layer winding machines are essential equipment for businesses that require precise and efficient winding of materials such as wire, cable, tubing, or tape. These machines are designed to wind materials onto spools or reels in a controlled manner, ensuring uniform tension and layering for optimal performance. Choosing the right precision layer winding machine for your business is crucial to achieving high-quality results and maximizing productivity. In this article, we will discuss key factors to consider when selecting a precision layer winding machine that meets your specific needs.

One of the first considerations when choosing a precision layer winding machine is the type of material you will be winding. Different materials have varying properties that can affect the winding process, such as thickness, flexibility, and tensile strength. It is important to select a machine that is designed to handle the specific characteristics of the material you will be working with to ensure smooth and efficient winding.

Another important factor to consider is the speed and capacity of the precision layer winding machine. The speed at which the machine can wind materials onto spools or reels will impact the overall productivity of your business. Additionally, the capacity of the machine, or the maximum size of spools or reels it can accommodate, will determine the amount of material that can be wound at one time. It is essential to choose a machine that can meet the production demands of your business while maintaining high-quality winding results.

In addition to material type, speed, and capacity, it is also important to consider the precision and accuracy of the winding process. Precision layer winding machines are designed to wind materials with consistent tension and layering to ensure uniformity and quality. Look for machines that offer features such as adjustable tension control, programmable winding patterns, and automatic stop functions to achieve precise winding results every time.

Furthermore, the ease of use and maintenance of the precision layer winding machine should also be taken into account. A user-friendly machine with intuitive controls and easy setup will help streamline the winding process and reduce the risk of errors. Additionally, a machine that is easy to maintain and service will minimize downtime and ensure continuous operation.

When selecting a precision layer winding machine for your business, it is important to consider the reputation and reliability of the manufacturer. Look for companies with a proven track record of producing high-quality winding machines and providing excellent customer support. Reading reviews and testimonials from other businesses that have used the machine can also help you gauge its performance and reliability.

In conclusion, choosing the right precision layer winding machine for your business is a critical decision that can impact the quality and efficiency of your production process. Consider factors such as material type, speed, capacity, precision, ease of use, and manufacturer reputation when selecting a machine that meets your specific needs. By investing in a high-quality precision layer winding machine, you can ensure consistent and reliable winding results that will help drive the success of your business.