Table of Contents

Tips for Maximizing Efficiency with Horizontal Spooler Of Wire Drawing Machine Process

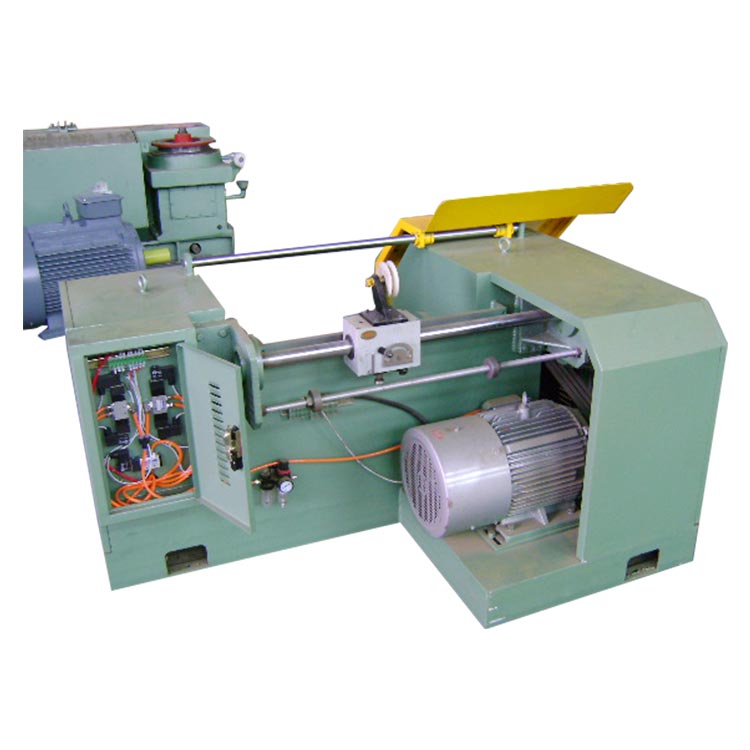

Wire drawing machines are essential tools in the manufacturing industry for producing wire of various diameters and materials. One crucial component of a wire drawing machine is the horizontal spooler, which plays a vital role in the wire drawing process. In this article, we will discuss some tips for maximizing efficiency with a horizontal spooler in the wire drawing machine process.

First and foremost, it is essential to ensure that the horizontal spooler is properly set up and maintained. This includes checking for any loose or damaged parts, lubricating moving components, and ensuring that the spooler is aligned correctly with the rest of the wire drawing machine. Regular maintenance and inspection of the horizontal spooler will help prevent breakdowns and downtime, ultimately increasing efficiency in the wire drawing process.

Another tip for maximizing efficiency with a horizontal spooler is to pay attention to the tension of the wire being wound onto the spool. Proper tension is crucial for achieving consistent wire quality and preventing snags or breaks in the wire. Adjusting the tension settings on the horizontal spooler according to the wire diameter and material being drawn will help ensure smooth operation and optimal wire quality.

In addition to maintaining proper tension, it is also important to monitor the speed at which the wire is being drawn and wound onto the spool. Adjusting the speed settings on the horizontal spooler to match the speed of the wire drawing machine will help prevent overstretching or snapping of the wire, leading to higher efficiency and better wire quality.

Furthermore, using high-quality spools and spooling equipment can also help maximize efficiency in the wire drawing process. Investing in durable spools that can withstand the rigors of continuous use will help prevent premature wear and tear, reducing the risk of downtime and maintenance costs. Additionally, using spooling equipment with advanced features such as automatic tension control and speed adjustment can further improve efficiency and productivity in the wire drawing process.

Lastly, proper training and supervision of operators working with the horizontal spooler are essential for maximizing efficiency in the wire drawing process. Operators should be trained on how to operate the spooler safely and effectively, as well as how to troubleshoot common issues that may arise during operation. Supervisors should also regularly monitor the performance of the horizontal spooler and provide feedback and guidance to operators to ensure optimal efficiency and productivity.

In conclusion, maximizing efficiency with a horizontal spooler in the wire drawing machine process requires proper setup, maintenance, and operation of the spooler. By following the tips outlined in this article, manufacturers can ensure smooth operation, consistent wire quality, and increased productivity in their wire drawing processes. Investing in high-quality spools and spooling equipment, monitoring tension and speed settings, and providing proper training to operators are all key factors in achieving maximum efficiency with a horizontal spooler.

Benefits of Using a Horizontal Spooler in Wire Drawing Machine Process

Wire drawing is a process used to reduce the diameter of a wire by pulling it through a series of dies. This process is commonly used in industries such as automotive, construction, and electronics to produce wires of various sizes and shapes. One crucial component of the wire drawing process is the spooler, which is used to wind the drawn wire onto a spool for storage and transportation.

There are two main types of Bobbin Spooling Machine used in wire drawing machines: vertical spoolers and horizontal spoolers. While both types serve the same purpose, there are distinct advantages to using a horizontal spooler in the wire drawing process.

One of the primary benefits of using a horizontal spooler is its space-saving design. Horizontal spoolers are typically more compact than vertical spoolers, making them ideal for facilities with limited space. This can help companies optimize their production floor layout and maximize efficiency in their wire drawing operations.

Additionally, horizontal spoolers offer greater flexibility in terms of spool size and configuration. Because the spools are positioned horizontally, they can accommodate a wider range of spool sizes and shapes, allowing for more customization in the winding process. This flexibility is especially beneficial for companies that produce wires of varying diameters and lengths.

Another advantage of using a horizontal spooler is its ease of operation. Horizontal spoolers are designed to be user-friendly, with intuitive controls and easy access to the spooling area. This can help reduce downtime and increase productivity in the wire drawing process, as operators can quickly and efficiently load and unload spools as needed.

Furthermore, horizontal spoolers are known for their reliability and durability. These spoolers are built to withstand the rigors of continuous operation, ensuring consistent performance over time. This reliability is essential in industries where downtime can result in costly production delays.

In addition to their practical benefits, horizontal spoolers also offer aesthetic advantages. The horizontal orientation of the spools creates a clean and organized appearance in the production area, which can contribute to a more efficient and professional work environment.

Overall, the use of a horizontal spooler in the wire drawing process can provide numerous benefits for companies looking to optimize their production operations. From space-saving design to flexibility in spool size and configuration, horizontal spoolers offer a range of advantages that can help companies improve efficiency, productivity, and overall performance in their wire drawing operations.

In conclusion, the horizontal spooler is a valuable component of the wire drawing machine process, offering a range of benefits that can help companies streamline their production operations and achieve greater success in the competitive marketplace. By investing in a horizontal spooler, companies can enhance their wire drawing capabilities and position themselves for long-term growth and profitability.