Table of Contents

Maintenance Tips for Water-Tank Wire Drawing Machines

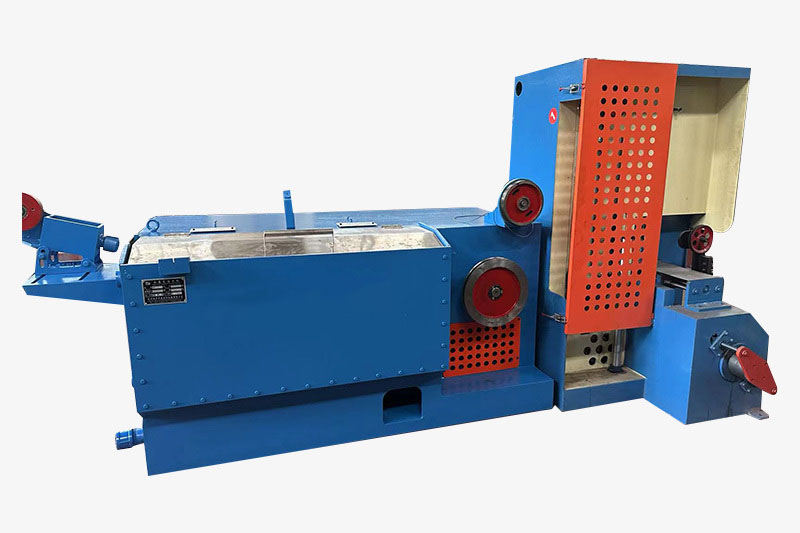

Water-tank wire drawing machines are essential equipment in the wire manufacturing industry. These machines are used to draw wire through a series of dies to reduce its diameter and improve its quality. Proper maintenance of water-tank wire drawing machines is crucial to ensure their optimal performance and longevity. In this article, we will discuss some maintenance tips for water-tank wire drawing machines to help you keep them in top condition.

Regular cleaning of the water tank is essential to prevent the buildup of dirt, debris, and other contaminants that can affect the quality of the wire being drawn. It is recommended to clean the water tank at least once a week to remove any impurities that may have accumulated. Use a mild detergent and a soft brush to scrub the tank thoroughly, and rinse it with clean water to remove any residue.

Inspect the water tank for any signs of corrosion or damage regularly. Corrosion can weaken the tank and lead to leaks, which can affect the drawing process and the quality of the wire. If you notice any signs of corrosion, such as rust spots or pitting, it is important to address the issue promptly. You may need to replace the affected parts or apply a protective coating to prevent further corrosion.

Check the water level in the tank regularly to ensure that it is at the appropriate level. The water level should be sufficient to provide adequate cooling during the wire drawing process. If the water level is too low, it can lead to overheating of the dies and affect the quality of the wire. Add water as needed to maintain the proper level and ensure optimal cooling.

Inspect the water circulation system of the wire drawing machine to ensure that it is functioning properly. The water circulation system is responsible for cooling the dies and maintaining the temperature of the water in the tank. Check the pump, hoses, and fittings for any signs of leaks or damage, and replace any faulty components as needed. Proper water circulation is essential to prevent overheating of the dies and ensure consistent wire quality.

Regularly lubricate the moving parts of the Slip Wire Drawing Machine to reduce friction and wear. Lubrication helps to prolong the life of the machine and ensure smooth operation. Use a high-quality lubricant recommended by the manufacturer and apply it to the bearings, gears, and other moving parts according to the manufacturer’s instructions. Avoid over-lubricating, as this can attract dirt and debris that can affect the performance of the machine.

Inspect the electrical components of the wire drawing machine regularly to ensure that they are in good working condition. Check the wiring, switches, and controls for any signs of damage or wear, and replace any faulty components immediately. Proper maintenance of the electrical system is essential to prevent malfunctions and ensure the safety of the operators.

In conclusion, proper maintenance of water-tank wire drawing machines is essential to ensure their optimal performance and longevity. By following these maintenance tips, you can keep your wire drawing machine in top condition and prolong its service life. Regular cleaning, inspection, lubrication, and monitoring of the water circulation system and electrical components are key aspects of maintaining a water-tank wire drawing machine. By taking care of your machine, you can ensure consistent wire quality and maximize productivity in your wire manufacturing operations.

Benefits of Using Water-Tank Wire Drawing Machines

Water-tank wire drawing machines are a crucial piece of equipment in the wire manufacturing industry. These machines are designed to draw wire through a series of dies to reduce its diameter and improve its quality. One of the main benefits of using Wet Wire Drawing Machine is their ability to produce high-quality wire with consistent diameter and surface finish.

The water-tank in these machines plays a key role in the wire drawing process. As the wire is pulled through the dies, it generates heat due to friction. The water in the tank helps to cool the wire down, preventing it from overheating and maintaining its structural integrity. This cooling process also helps to improve the surface finish of the wire, resulting in a smoother and more uniform product.

Another benefit of using water-tank wire drawing machines is their versatility. These machines can be used to draw a wide range of wire sizes and materials, making them suitable for a variety of applications. Whether you need to produce thin wire for electronics or thick wire for construction, a water-tank wire drawing machine can meet your requirements.

In addition to their versatility, water-tank wire drawing machines are also highly efficient. These machines are designed to operate at high speeds, allowing manufacturers to produce large quantities of wire in a short amount of time. This efficiency not only increases productivity but also reduces production costs, making water-tank wire drawing machines a cost-effective solution for wire manufacturers.

Furthermore, water-tank wire drawing machines are known for their durability and reliability. These machines are built to withstand the rigors of continuous operation, ensuring consistent performance over time. With proper maintenance and care, a water-tank wire drawing machine can last for many years, providing manufacturers with a reliable and long-lasting solution for their wire drawing needs.

One of the key advantages of using water-tank wire drawing machines is their ability to produce wire with precise diameter control. The dies in these machines are carefully calibrated to ensure that the wire is drawn to the exact specifications required by the manufacturer. This level of precision is essential for industries that require high-quality wire with tight tolerances, such as the automotive and aerospace sectors.

In conclusion, water-tank wire drawing machines offer a wide range of benefits for wire manufacturers. From producing high-quality wire with consistent diameter and surface finish to their versatility, efficiency, durability, and precision, these machines are an essential tool for the wire manufacturing industry. By investing in a water-tank wire drawing machine, manufacturers can improve their production processes, increase productivity, and ultimately, enhance the quality of their products.