Understand the Advantages of Using Inverted Vertical Wire Drawing Machinery

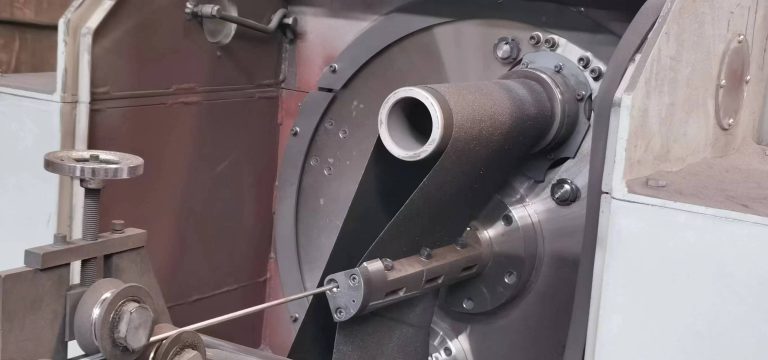

Inverted vertical wire drawing machinery is a type of equipment used in the manufacturing industry to produce wire of various diameters and materials. This type of machinery offers several advantages over traditional horizontal wire drawing machines, making it a popular choice for many manufacturers.

One of the primary advantages of using Inverted High Speed Vertical Wire Drawing Machine is its space-saving design. Unlike horizontal wire drawing machines, which require a large amount of floor space, inverted vertical machines are designed to be compact and efficient. This makes them ideal for manufacturers with limited space in their facilities, allowing them to maximize their production capabilities without sacrificing valuable floor space.

In addition to their space-saving design, inverted vertical wire drawing machines also offer improved operator safety. By positioning the wire drawing process vertically, operators are able to work at a more ergonomic height, reducing the risk of strain and injury. This can lead to a safer and more productive work environment, ultimately benefiting both the employees and the company as a whole.

Another advantage of using inverted vertical wire drawing machinery is its ability to produce wire with a higher level of precision and consistency. The vertical orientation of the machine allows for better control over the drawing process, resulting in wire that meets tighter tolerances and specifications. This is particularly important for manufacturers producing wire for specialized applications, such as medical devices or aerospace components, where precision is critical.

Furthermore, inverted vertical wire drawing machinery is also known for its versatility. These machines are capable of drawing wire from a wide range of materials, including steel, aluminum, copper, and more. This flexibility allows manufacturers to produce wire for a variety of applications, making the machinery a valuable asset for companies with diverse product lines.

Additionally, inverted vertical wire drawing machinery is often equipped with advanced automation and control systems, further enhancing its efficiency and productivity. These systems allow for precise control over the drawing process, reducing the risk of human error and ensuring consistent, high-quality wire production. This level of automation can also lead to cost savings for manufacturers, as it reduces the need for manual labor and minimizes material waste.

In conclusion, inverted vertical wire drawing machinery offers several advantages over traditional horizontal wire drawing machines. Its space-saving design, improved operator safety, precision and consistency, versatility, and advanced automation and control systems make it a valuable asset for manufacturers in a wide range of industries. By investing in inverted vertical wire drawing machinery, companies can improve their production capabilities, enhance the quality of their products, and ultimately gain a competitive edge in the market.