Table of Contents

Advantages of Using Steel Wire Dead Block Coilers for Continuous Coiling

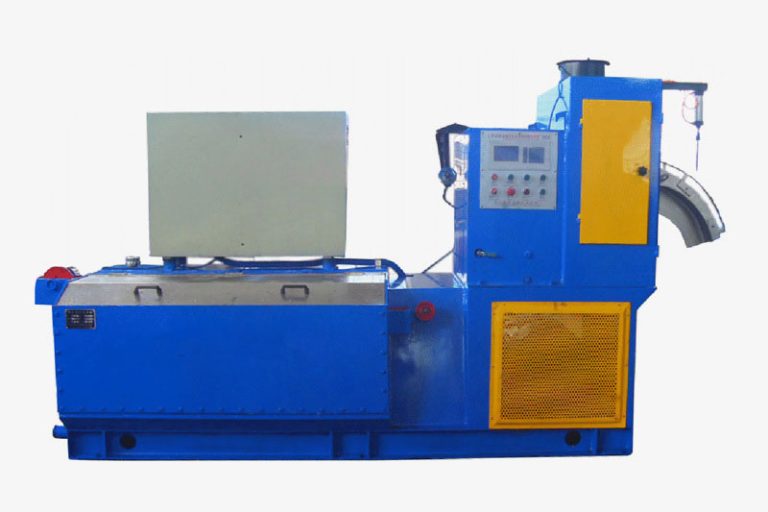

Steel wire dead block coilers are an essential piece of equipment in the wire manufacturing industry. These machines are used for continuous coiling of steel wire, providing numerous advantages to manufacturers. In this article, we will explore the benefits of using a Steel Wire Dead Block Coiler For Continuous Coiling.

One of the primary advantages of using a steel wire dead block coiler is its efficiency. These machines are designed to coil wire continuously, without the need for manual intervention. This results in a significant increase in productivity, as the coiling process can run uninterrupted for long periods of time. This efficiency not only saves time but also reduces labor costs, making the manufacturing process more cost-effective.

In addition to efficiency, steel wire dead block coiler for continuous coiling also offer precision in coiling. These machines are equipped with advanced technology that allows for precise control over the coiling process. This ensures that the wire is coiled evenly and accurately, resulting in high-quality finished products. The precision offered by steel wire dead block coilers is essential for industries that require consistent and uniform coiling of wire.

Another advantage of using a steel wire dead block coiler is its versatility. These machines can handle a wide range of wire diameters and coil sizes, making them suitable for various applications. Whether you are coiling thin wire for electronics or thick wire for construction, a steel wire dead block coiler can accommodate your needs. This versatility makes these machines a valuable asset for manufacturers with diverse product lines.

Furthermore, steel wire dead block coilers are known for their durability and reliability. These machines are built to withstand the rigors of continuous operation, ensuring long-term performance and minimal downtime. This reliability is crucial for manufacturers who depend on consistent production to meet customer demands. With a steel wire dead block coiler, you can trust that your coiling process will run smoothly and efficiently.

Additionally, steel wire dead block coilers are easy to maintain. These machines are designed for simple upkeep, with accessible components that can be easily serviced or replaced. This ease of maintenance helps to minimize downtime and prolong the lifespan of the equipment, saving manufacturers time and money in the long run. By investing in a steel wire dead block coiler, you can ensure that your coiling process remains efficient and reliable for years to come.

In conclusion, the advantages of using a steel wire dead block coiler for continuous coiling are clear. From increased efficiency and precision to versatility and reliability, these machines offer numerous benefits to manufacturers in the wire industry. By investing in a steel wire dead block coiler, you can streamline your coiling process, improve product quality, and reduce costs. If you are looking to enhance your wire manufacturing operations, consider the advantages of using a steel wire dead block coiler for continuous coiling.

How to Properly Maintain and Operate a Steel Wire Dead Block Coiler

Steel wire dead block coilers are essential equipment in the wire manufacturing industry. They are used to coil steel wire into compact and uniform coils for easy handling and transportation. Proper maintenance and operation of a steel wire dead block coiler are crucial to ensure its efficiency and longevity. In this article, we will discuss some important tips on how to properly maintain and operate a steel wire dead block coiler.

First and foremost, regular maintenance is key to keeping your steel wire dead block coiler in optimal condition. This includes cleaning the machine regularly to remove any dirt, dust, or debris that may accumulate on the equipment. It is also important to lubricate the moving parts of the coiler to prevent wear and tear. Regular inspection of the machine for any signs of damage or malfunction is also essential to prevent any potential breakdowns.

In addition to regular maintenance, proper operation of the steel wire dead block coiler is equally important. It is crucial to follow the manufacturer’s guidelines and instructions for operating the machine. This includes setting the correct tension and speed for coiling the steel wire, as well as ensuring that the wire is fed into the coiler properly to prevent any jams or tangles.

When operating the steel wire dead block coiler, it is important to pay attention to any unusual noises or vibrations coming from the machine. These may be signs of a potential problem that needs to be addressed immediately. It is also important to monitor the coil size and shape to ensure that they meet the required specifications.

Proper training of operators is also essential for the safe and efficient operation of a steel wire dead block coiler. Operators should be trained on how to use the machine correctly and safely, as well as how to troubleshoot any issues that may arise during operation. It is also important to provide operators with the necessary personal protective equipment to ensure their safety while operating the coiler.

In conclusion, proper maintenance and operation of a steel wire dead block coiler are essential to ensure its efficiency and longevity. Regular maintenance, following manufacturer’s guidelines, and proper training of operators are key to keeping the machine in optimal condition. By following these tips, you can ensure that your steel wire dead block coiler operates smoothly and efficiently, allowing you to produce high-quality steel wire coils for your customers.