Table of Contents

Merits of Using Belt Descaler in Industrial Applications

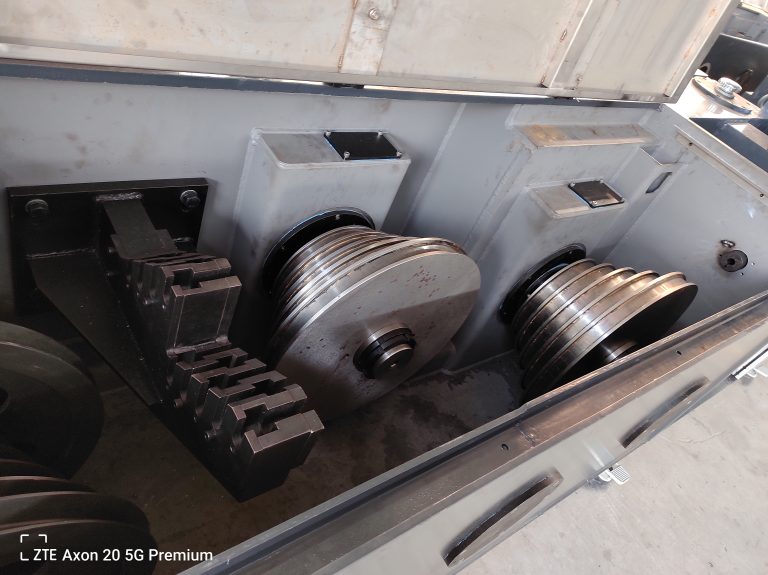

Belt Descaling Machine is an essential tool in industrial applications for maintaining the efficiency and longevity of conveyor belts. These devices are designed to remove debris, dirt, and other contaminants that can accumulate on the surface of the belt, causing wear and tear over time. By regularly using a belt descaler, companies can ensure that their conveyor belts operate smoothly and efficiently, reducing the risk of costly downtime and repairs.

One of the key benefits of using a belt descaler is the prevention of material buildup on the belt surface. Over time, materials such as dust, dirt, and grease can accumulate on the belt, causing it to become less effective in transporting goods. This buildup can also lead to increased friction between the belt and the pulleys, resulting in increased wear and tear on the belt. By using a belt descaler regularly, companies can prevent material buildup and ensure that their conveyor belts operate at peak efficiency.

In addition to preventing material buildup, belt descalers can also help to extend the life of conveyor belts. By removing contaminants from the belt surface, these devices can reduce the amount of wear and tear that the belt is subjected to during operation. This can help to prolong the life of the belt, saving companies money on costly replacements and repairs. In the long run, investing in a belt descaler can help companies to save money and improve the overall efficiency of their operations.

Another benefit of using a belt descaler is the improved safety that it provides. Conveyor belts that are covered in debris and contaminants can pose a safety hazard to workers, as they can become slippery and difficult to navigate. By regularly cleaning the belt surface with a descaler, companies can reduce the risk of accidents and injuries in the workplace. This can help to create a safer working environment for employees and reduce the likelihood of costly lawsuits and insurance claims.

Furthermore, belt descalers can also help to improve the overall cleanliness of industrial facilities. By removing debris and contaminants from conveyor belts, these devices can help to prevent the spread of dirt and dust throughout the facility. This can help to create a cleaner and more hygienic working environment for employees, reducing the risk of respiratory problems and other health issues. Additionally, a clean facility can help to improve the overall image of a company, making it more attractive to customers and investors.

In conclusion, Sanding Belt Grinding Descaler is an essential tool for maintaining the efficiency and longevity of conveyor belts in industrial applications. By regularly using a descaler, companies can prevent material buildup, extend the life of their belts, improve safety in the workplace, and create a cleaner working environment. Investing in a belt descaler can help companies to save money on costly repairs and replacements, while also improving the overall efficiency of their operations. Overall, belt descalers are a valuable asset for any company looking to optimize their conveyor belt maintenance practices.

How to Choose the Right Belt Descaler for Your Needs

When it comes to industrial equipment maintenance, choosing the right tools for the job is crucial. One such tool that is essential for keeping conveyor belts in top condition is a belt descaler. Belt descalers are used to remove debris, buildup, and other contaminants from conveyor belts, ensuring smooth operation and preventing costly downtime.

There are several factors to consider when choosing a belt descaler for your specific needs. The first thing to consider is the type of conveyor belt you have. Different types of belts require different types of descalers, so it is important to match the descaler to the belt material to ensure effective cleaning without causing damage.

Another important factor to consider is the size of the conveyor belt. Belt descalers come in a variety of sizes, so it is important to choose one that is appropriate for the size of your belt. Using a descaler that is too small may not effectively clean the entire belt, while using one that is too large may be cumbersome and inefficient.

In addition to size, it is also important to consider the cleaning method used by the descaler. Some descalers use brushes or scrapers to remove debris, while others use high-pressure water jets or steam. The best cleaning method for your needs will depend on the type and amount of debris on your conveyor belt, as well as any specific cleaning requirements you may have.

It is also important to consider the frequency of cleaning when choosing a belt descaler. Some descalers are designed for daily use, while others are more suited for periodic deep cleaning. If your conveyor belt requires frequent cleaning, it may be worth investing in a descaler that is designed for daily use to ensure optimal performance.

Cost is another important factor to consider when choosing a belt descaler. While it may be tempting to choose the cheapest option available, it is important to consider the long-term costs of maintenance and replacement. Investing in a high-quality descaler may cost more upfront, but it can save you money in the long run by preventing costly repairs and downtime.

When choosing a sanding belt grinding descaler, it is also important to consider the ease of use and maintenance. Look for a descaler that is easy to operate and maintain, with clear instructions and minimal downtime for cleaning and maintenance. Some descalers may also come with additional features, such as automatic cleaning cycles or adjustable settings, that can make maintenance easier and more efficient.

In conclusion, choosing the right belt descaler for your needs is essential for maintaining the performance and longevity of your conveyor belt. Consider factors such as belt type, size, cleaning method, frequency of cleaning, cost, and ease of use when making your decision. By investing in a high-quality descaler that is suited to your specific needs, you can ensure smooth operation and prevent costly downtime.

Top Tips for Maintaining and Extending the Lifespan of Your Belt Descaler

Maintaining and extending the lifespan of your belt descaler is crucial for ensuring optimal performance and efficiency in your industrial operations. A belt descaler is a vital piece of equipment used in various industries to remove scale and other deposits from conveyor belts, ensuring smooth operation and preventing damage to the belt and other machinery. To maximize the effectiveness and longevity of your belt descaler, it is essential to follow a few key tips and best practices.

Regular cleaning and maintenance are essential for keeping your belt descaler in top condition. Over time, scale and other deposits can build up on the descaling brushes, reducing their effectiveness and potentially causing damage to the conveyor belt. To prevent this, it is important to regularly inspect the brushes and clean them as needed. This can be done by removing the brushes from the descaler and washing them with a mild detergent to remove any buildup. Additionally, it is important to check the alignment of the brushes and adjust them if necessary to ensure they are making proper contact with the belt.

In addition to regular cleaning, it is important to inspect the overall condition of the belt descaler on a regular basis. This includes checking for any signs of wear or damage, such as worn brushes or damaged components. If any issues are identified, it is important to address them promptly to prevent further damage and ensure the continued effectiveness of the descaler. This may involve replacing worn brushes, repairing damaged components, or performing other maintenance tasks as needed.

Proper lubrication is also essential for maintaining the performance and longevity of your belt descaler. The moving parts of the descaler, such as the brushes and bearings, should be lubricated regularly to reduce friction and prevent wear. It is important to use the correct type of lubricant for each component and to follow the manufacturer’s recommendations for lubrication intervals. Over-lubrication can be just as damaging as under-lubrication, so it is important to use the right amount of lubricant and to avoid applying it too frequently.

Another important tip for maintaining your belt descaler is to ensure that it is operated correctly. This includes following the manufacturer’s guidelines for operation and maintenance, as well as training employees on the proper use of the equipment. Improper operation can lead to premature wear and damage to the descaler, so it is important to ensure that all operators are properly trained and follow best practices when using the equipment.

In conclusion, maintaining and extending the lifespan of your belt descaler is essential for ensuring optimal performance and efficiency in your industrial operations. By following these tips and best practices, you can keep your descaler in top condition and prevent costly downtime and repairs. Regular cleaning and maintenance, inspecting the condition of the descaler, proper lubrication, and correct operation are all key factors in maximizing the effectiveness and longevity of your belt descaler. By taking care of your equipment and following these guidelines, you can ensure that your belt descaler continues to provide reliable service for years to come.