Table of Contents

Benefits of Using Automatic Wire Straightening and Cutting Machines

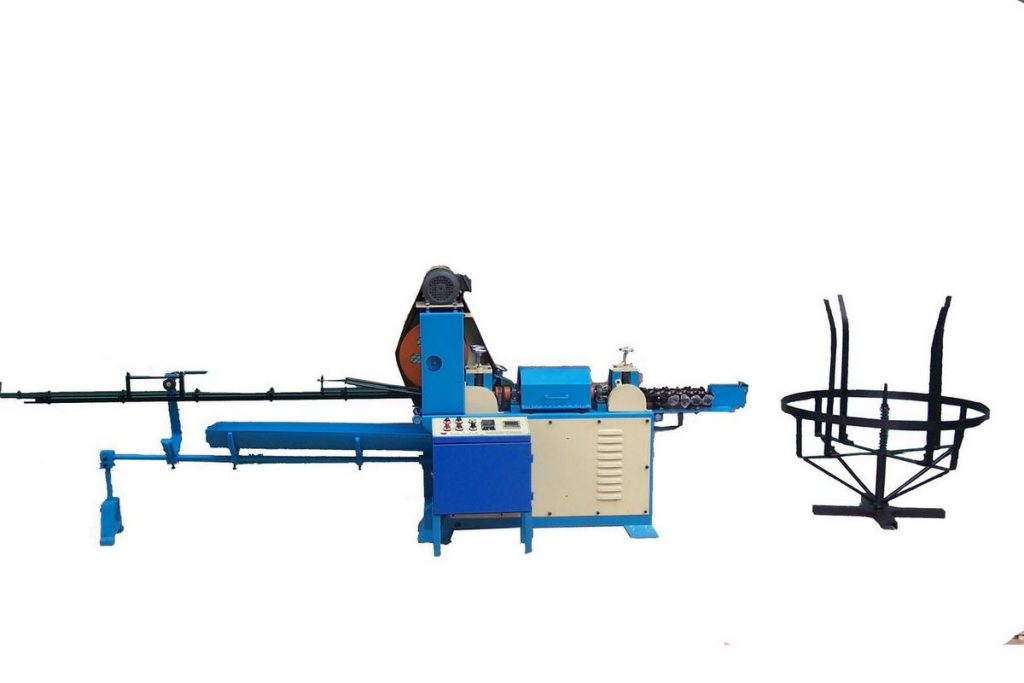

Wire Straightening and Cutting Machines are essential tools in the manufacturing industry, especially in the production of wire-based products such as fences, nails, and wires for construction and industrial applications. These machines are designed to straighten and cut wires quickly and accurately, saving time and labor costs for manufacturers. In recent years, automatic wire straightening and cutting machines have become increasingly popular due to their efficiency and precision.

One of the key benefits of using automatic wire straightening and cutting machines is their ability to increase productivity. These machines are equipped with advanced technology that allows them to straighten and cut wires at a much faster rate than manual methods. This means that manufacturers can produce more wire-based products in a shorter amount of time, leading to increased output and higher profits.

In addition to increasing productivity, automatic wire straightening and cutting machines also improve the quality of the end product. These machines are designed to straighten and cut wires with a high level of precision, ensuring that each piece is uniform in size and shape. This is especially important in industries where consistency is key, such as the construction and automotive sectors.

Another benefit of using automatic wire straightening and cutting machines is their ease of use. These machines are equipped with user-friendly interfaces that allow operators to set the desired parameters quickly and easily. This means that even workers with minimal training can operate the machines effectively, reducing the need for skilled labor and training costs.

Furthermore, automatic wire straightening and cutting machines are also safer to use than manual methods. These machines are equipped with safety features such as emergency stop buttons and guards to prevent accidents and injuries. This not only protects workers from harm but also reduces the risk of damage to the machines and the products being manufactured.

Additionally, automatic wire straightening and cutting machines are more cost-effective in the long run. While the initial investment may be higher than manual methods, the increased productivity and efficiency of these machines lead to lower production costs over time. This means that manufacturers can recoup their investment quickly and enjoy higher profits in the long term.

Overall, automatic wire straightening and cutting machines offer a range of benefits for manufacturers in various industries. From increased productivity and improved product quality to ease of use and cost-effectiveness, these machines are a valuable asset for any manufacturing operation. By investing in automatic wire straightening and cutting machines, manufacturers can streamline their production processes, increase output, and stay ahead of the competition in today’s fast-paced market.

How to Choose the Right Automatic Wire Straightening and Cutting Machine for Your Needs

Wire straightening and cutting machines are essential tools in the manufacturing industry, especially for companies that work with wire on a regular basis. These machines help to streamline the production process by automatically straightening and cutting wire to the desired length, saving time and labor costs. If you are in the market for an automatic wire straightening and cutting machine, there are several factors to consider to ensure you choose the right one for your needs.

One of the first things to consider when selecting a wire straightening and cutting machine is the type of wire you will be working with. Different machines are designed to handle different types of wire, so it is important to choose a machine that is compatible with the wire you will be using. Whether you are working with steel, aluminum, copper, or another type of wire, make sure the machine you choose is capable of handling the specific material.

Another important factor to consider is the diameter of the wire you will be working with. Wire straightening and cutting machines come in a variety of sizes to accommodate different wire diameters, so it is crucial to choose a machine that can handle the diameter of wire you will be using. Using a machine that is not designed for the diameter of wire you are working with can result in damage to the machine and poor quality cuts.

In addition to the type and diameter of wire, it is also important to consider the length of wire you will be cutting. Some wire straightening and cutting machines are designed to cut wire to a specific length, while others are adjustable and can cut wire to varying lengths. If you will be cutting wire to a specific length, make sure the machine you choose is capable of cutting wire to that length consistently and accurately.

When choosing an automatic wire straightening and cutting machine, it is also important to consider the speed and efficiency of the machine. Some machines are capable of straightening and cutting wire at a faster rate than others, which can help to increase productivity and reduce production time. Additionally, machines with automatic feeding and cutting mechanisms can further streamline the production process and improve efficiency.

Finally, it is important to consider the overall quality and reliability of the machine. Look for a machine that is made from durable materials and is built to last. Additionally, consider the reputation of the manufacturer and read reviews from other customers to ensure you are choosing a machine that is reliable and will meet your needs.

In conclusion, choosing the right automatic wire straightening and cutting machine for your needs requires careful consideration of the type of wire, diameter, length, speed, efficiency, and overall quality of the machine. By taking the time to research and evaluate your options, you can select a machine that will help to improve productivity, reduce labor costs, and streamline your production process.

Maintenance Tips for Ensuring Longevity of Automatic Wire Straightening and Cutting Machines

Wire straightening and cutting machines are essential tools in various industries that require precise cutting and straightening of wires. These machines are designed to automate the process, increasing efficiency and accuracy. However, like any other machinery, automatic wire straightening and cutting machines require regular maintenance to ensure longevity and optimal performance.

One of the most important maintenance tips for automatic wire straightening and cutting machines is to regularly inspect and clean the machine. Dust, debris, and other contaminants can build up on the machine’s components, leading to decreased performance and potential damage. By regularly cleaning the machine, you can prevent these issues and ensure that it continues to operate smoothly.

In addition to cleaning, it is crucial to regularly lubricate the moving parts of the machine. Lubrication helps reduce friction and wear on the components, extending the machine’s lifespan. Be sure to use the appropriate lubricant for the machine’s specific requirements and follow the manufacturer’s recommendations for lubrication intervals.

Another important maintenance tip is to regularly check and adjust the machine’s settings. Over time, the machine’s settings may drift out of alignment, leading to inaccuracies in wire cutting and straightening. By regularly checking and adjusting the settings, you can ensure that the machine continues to produce precise results.

It is also essential to inspect the cutting blades regularly. Dull or damaged blades can lead to uneven cuts and damage to the wire. If you notice any signs of wear or damage on the blades, replace them immediately to prevent further issues.

Regularly inspecting the machine’s electrical components is another crucial maintenance tip. Loose connections, worn wires, or damaged components can lead to electrical issues that can affect the machine’s performance. By inspecting the electrical components regularly, you can identify and address any potential issues before they cause significant problems.

Additionally, it is important to keep the machine’s workspace clean and organized. Cluttered workspaces can increase the risk of accidents and damage to the machine. By keeping the workspace clean and organized, you can create a safe and efficient working environment for the machine.

Lastly, it is essential to follow the manufacturer’s recommended maintenance schedule for the machine. Regular maintenance tasks, such as cleaning, lubricating, and inspecting the machine, should be performed at specified intervals to ensure optimal performance and longevity. By following the manufacturer’s recommendations, you can prevent potential issues and keep the machine running smoothly.

In conclusion, regular maintenance is essential for ensuring the longevity and optimal performance of automatic wire straightening and cutting machines. By following these maintenance tips, you can prevent issues, extend the machine’s lifespan, and ensure that it continues to produce precise results. Remember to regularly clean, lubricate, inspect, and adjust the machine to keep it in top condition. By investing time and effort into maintenance, you can maximize the efficiency and lifespan of your automatic wire straightening and cutting machine.