Table of Contents

Advantages of Using Layer Winding Machines in Industrial Applications

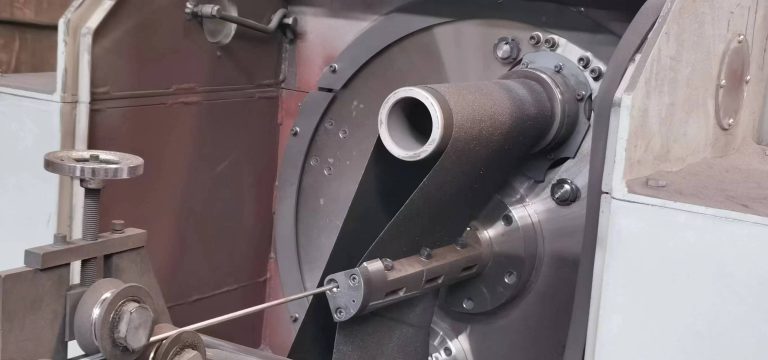

Layer winding machines are an essential tool in many industrial applications, providing numerous advantages that help streamline production processes and improve overall efficiency. These machines are designed to wind materials, such as wire, cable, or tubing, onto spools or reels in a precise and controlled manner. By automating the winding process, layer winding machines offer several key benefits that make them a valuable asset in various industries.

One of the primary advantages of using layer winding machines is their ability to increase productivity. These machines are capable of winding materials at a much faster rate than manual methods, allowing companies to produce more finished products in less time. This increased efficiency can lead to cost savings and improved profitability for businesses, making layer winding machines a worthwhile investment for many industrial applications.

In addition to boosting productivity, layer winding machines also offer greater precision and consistency in the winding process. By using automated controls and sensors, these machines can ensure that each layer of material is wound onto the spool or reel with the exact tension and alignment required. This level of precision is difficult to achieve with manual winding methods, which can lead to inconsistencies and defects in the finished product. With a layer winding machine, companies can produce high-quality materials that meet strict specifications and standards.

Another advantage of using layer winding machines is their versatility. These machines can be customized to accommodate a wide range of materials and spool sizes, making them suitable for a variety of industrial applications. Whether winding thin wire for electronics or thick cable for construction, layer winding machines can be tailored to meet the specific needs of each project. This flexibility allows companies to use a single machine for multiple tasks, reducing the need for additional equipment and saving valuable floor space in the production facility.

Furthermore, layer winding machines can help improve workplace safety by reducing the risk of injuries associated with manual winding processes. By automating the winding process, these machines eliminate the need for workers to handle materials directly, minimizing the potential for accidents and ergonomic strain. This can create a safer and more comfortable working environment for employees, leading to higher morale and productivity in the long run.

Overall, layer winding machines offer a wide range of advantages for industrial applications, including increased productivity, precision, versatility, and safety. By investing in these machines, companies can streamline their production processes, improve product quality, and enhance overall efficiency. With the ability to customize these machines to meet specific requirements, businesses can benefit from a versatile and reliable tool that can adapt to changing production needs. Layer winding machines are a valuable asset for any company looking to optimize their winding processes and stay competitive in today’s fast-paced industrial environment.

How to Choose the Right Layer Winding Machine for Your Production Needs

Layer winding machines are essential equipment in the manufacturing industry, particularly for companies that produce coils, transformers, and other wound components. These machines are designed to wind wire or other materials onto a spool or bobbin in a precise and controlled manner, ensuring uniformity and consistency in the final product. Choosing the right layer winding machine for your production needs is crucial to achieving high-quality results and maximizing efficiency.

When selecting a layer winding machine, there are several factors to consider to ensure that it meets your specific requirements. One of the most important considerations is the type of material you will be winding. Different machines are designed to handle different materials, such as wire, cable, or tape, so it is essential to choose a machine that is compatible with the material you will be working with.

Another important factor to consider is the size and shape of the components you will be winding. Some layer winding machines are designed for small, delicate components, while others are better suited for larger, heavier components. It is important to choose a machine that can accommodate the size and shape of the components you will be working with to ensure that they are wound correctly and securely.

The speed and accuracy of the layer winding machine are also crucial considerations. Some machines are capable of winding at high speeds, while others are designed for more precise, slow-speed winding. The speed and accuracy of the machine will depend on the specific requirements of your production process, so it is important to choose a machine that can meet these requirements.

In addition to speed and accuracy, the level of automation of the layer winding machine is another important consideration. Some machines are fully automated, with programmable controls and sensors that ensure precise winding every time. Other machines require more manual intervention, which can be time-consuming and less efficient. It is important to choose a machine that offers the level of automation that is appropriate for your production needs.

The quality and reliability of the layer winding machine are also important factors to consider. Investing in a high-quality machine from a reputable manufacturer will ensure that it performs reliably and consistently, minimizing downtime and maximizing productivity. It is important to research different manufacturers and models to find a machine that meets your quality and reliability standards.

Finally, the cost of the layer winding machine is an important consideration for many companies. While it is important to invest in a high-quality machine that meets your production needs, it is also important to consider your budget and choose a machine that offers the best value for your money. Comparing prices and features of different machines can help you find a machine that meets your requirements while staying within your budget.

In conclusion, choosing the right layer winding machine for your production needs is a crucial decision that can have a significant impact on the quality, efficiency, and cost-effectiveness of your manufacturing process. By considering factors such as the type of material, size and shape of components, speed and accuracy, level of automation, quality and reliability, and cost, you can find a machine that meets your specific requirements and helps you achieve your production goals. Investing in the right layer winding machine will ensure that your production process runs smoothly and efficiently, leading to high-quality products and satisfied customers.